Surface continuity, often referred to as “G0,” “G1,” “G2,” and so on, is a measure of the smoothness and continuity between adjacent surfaces in computer-aided design (CAD) and computer-aided manufacturing (CAM).

Here’s an explanation of each level of surface continuity:

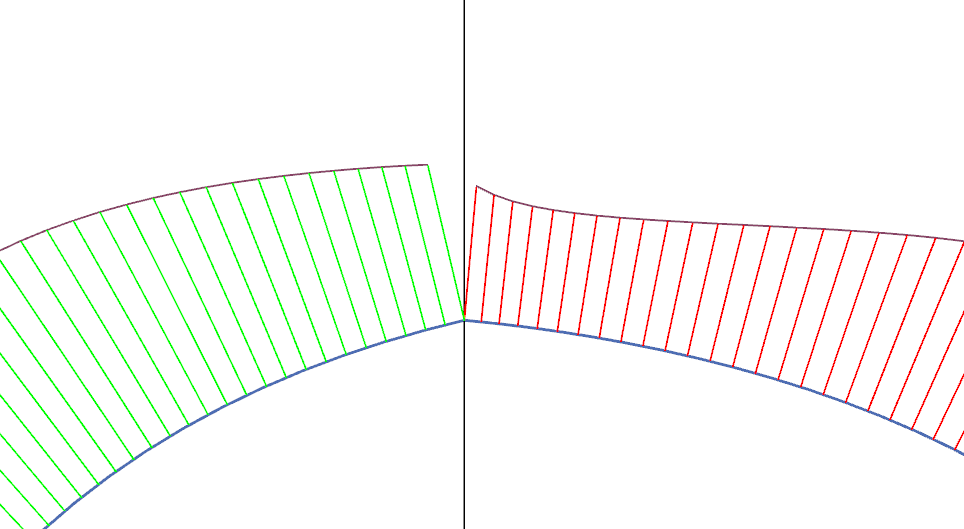

G0 (Positional Continuity): G0 continuity, also known as positional continuity, indicates that two surfaces meet without any gaps or overlaps. However, there is no requirement for smoothness or tangent continuity between the surfaces. The surfaces may have different slopes or curvatures at the junction, resulting in an angular or stepped transition.

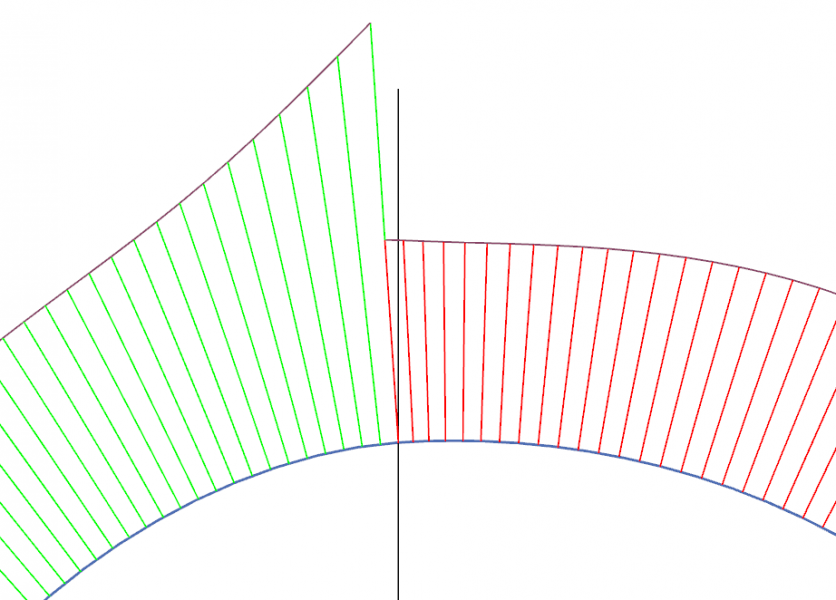

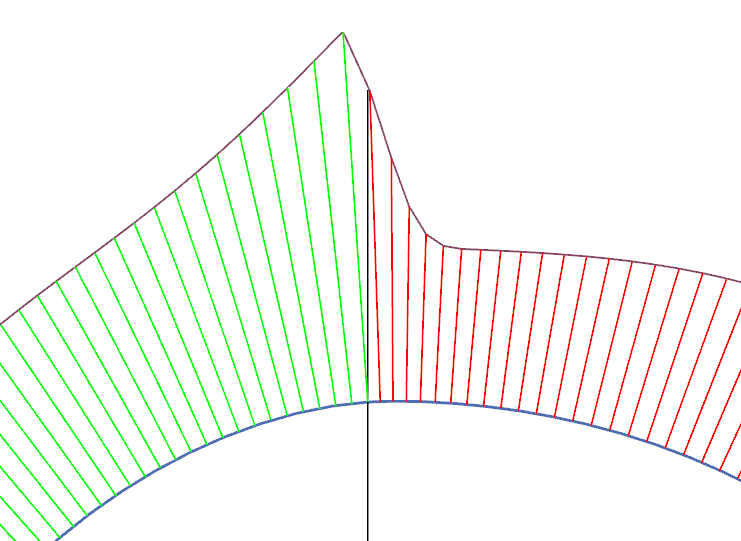

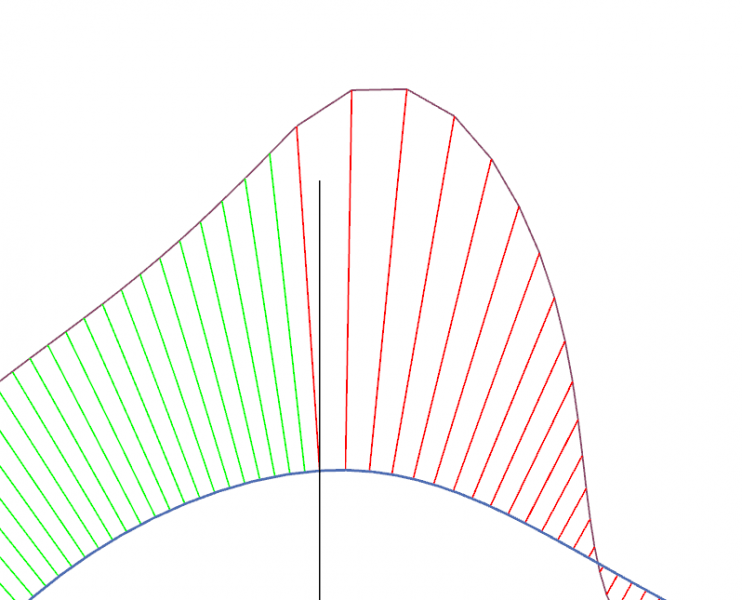

In these illustrations, the “combs” along the curve are perpendicular to the curve at the point where they attach, and have a length that is proportional to the degree of curvature. For example, a straight line would have zero length combs, a circle would have combs all the same length. The longer the combs, the tighter the curvature. It is important to notice how the combs reflect change in curvature, and how they relate at the connection between two curves.

G1 (Tangential Continuity): G1 continuity, or tangential continuity, requires that the surfaces not only meet without gaps or overlaps but also have a continuous tangent at the junction. In other words, the surfaces share the same slope or direction at the point of contact. This ensures a smooth transition, but the curvatures of the surfaces may still differ.

G2 (Curvature Continuity): G2 continuity, also called curvature continuity or geometric continuity, takes surface smoothness to the next level. In addition to meeting without gaps, the surfaces exhibit a continuous curvature at the junction. This means that the rate of change of the surface curvature matches seamlessly. The transition between the surfaces is visually smooth, and there are no abrupt changes in curvature.

G3 (Higher Order Continuity): G3 continuity, or higher order continuity, represents an even higher level of smoothness and continuity between surfaces. It requires not only tangent and curvature continuity but also ensures a continuous change in the rate of curvature throughout the transition. This level of continuity is often required for achieving aesthetic and aerodynamic surfaces, where the highest level of smoothness is desired.

The different levels of surface continuity, from G0 to G3, provide a means to specify the desired smoothness and continuity requirements between adjacent surfaces. Designers and manufacturers can use these continuity levels to communicate the desired quality and appearance of transitions between surfaces in CAD and CAM systems, ensuring the desired visual and functional characteristics of the final product.