Steel is a widely used alloy of iron and carbon, with carbon content typically ranging from 0.2% to 2.1% by weight. It is known for its high strength, durability, and versatility, making it a popular choice in a wide range of applications, including construction, manufacturing, and transportation. Steel can be produced in a variety of forms, including flat sheets, bars, tubes, and wire, and it can be easily fabricated and shaped using a variety of techniques, including welding, cutting, and forging. The specific properties of steel can be adjusted through the addition of other elements, such as manganese, nickel, and chromium, allowing for even greater versatility in its use.

There are many different categories of steel, with different compositions and properties that make them suitable for a range of applications. Some common categories of steel include:

Carbon steel: This is a basic form of steel that contains only carbon as the alloying element. Carbon steel is the most common type of steel and is used in a wide range of applications.

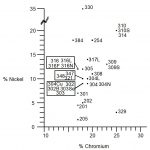

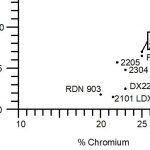

Alloy steel: This is steel that contains additional alloying elements besides carbon, such as manganese, chromium, nickel, or molybdenum. These elements are added to improve specific properties of the steel, such as strength or corrosion resistance.

Stainless steel: This is a type of steel that contains at least 10.5% chromium, which gives it its characteristic corrosion resistance. Stainless steel is commonly used in applications where resistance to corrosion is important, such as in the food and chemical processing industries.

Tool steel: This is a type of steel that is designed for use in tools and dies, where it needs to be hard and wear-resistant. Tool steel often contains additional alloying elements, such as tungsten or cobalt, to enhance its properties.