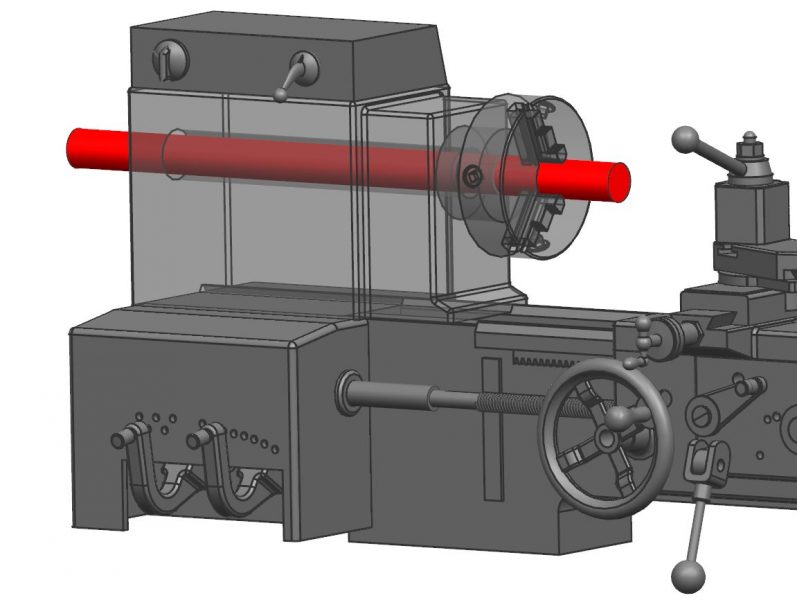

The spindle bore diameter, often simply referred to as the bore diameter, is a critical specification of a lathe machine. It represents the inside diameter of the hole or opening through the spindle, which is the rotating component responsible for holding and securing the workpiece during machining operations.

The spindle bore diameter specifies the size of the opening or passageway through the spindle, which is typically cylindrical in shape. It is expressed in either inches or millimeters and is a crucial specification for lathes. This specification is essential for determining the maximum diameter of a workpiece that can pass through the spindle and be held securely for machining. It is a critical factor when you need to work on larger workpieces, especially when you require the workpiece to extend beyond the spindle chuck or collet.It’s important to note that the bore diameter sets a practical upper limit on the workpiece size. Workpieces with diameters exceeding the spindle bore diameter cannot pass through and, therefore, cannot be machined on that particular lathe without additional modifications or setups.

The spindle bore is particularly significant when turning or machining workpieces like pipes, tubes, or bars. The bore diameter must be large enough to accommodate the workpiece’s diameter while providing sufficient space for the chuck or collet to grip it securely.

The size of the spindle bore diameter also influences the type and size of chucks or collets that can be used with the lathe. A spindle with a larger bore diameter can accommodate larger chucks or collets, expanding the range of workpiece sizes that can be machined.