Ferrous metals are a category of metals that contain iron as their main constituent element. The most common ferrous metals include carbon steel, alloy steel, stainless steel, cast iron, and wrought iron. These materials are widely used in engineering applications due to their high tensile strength, durability, and resistance to wear and tear. Additionally, ferrous...

Nonferrous metals are metals that do not contain iron as a major component. These metals have different properties and applications compared to ferrous metals. Common nonferrous metals include aluminum, copper, zinc, nickel, and titanium, among others. Nonferrous metals such as aluminum are extremely useful engineering materials. One of the most notable advantages of nonferrous metals...

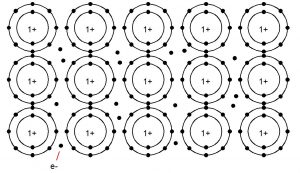

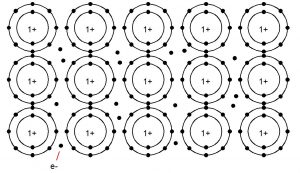

Metals represent a class of chemical elements defined by distinctive characteristics. They are recognized for their metallic luster, high electrical conductivity, malleability, and ductility. hat sets metals apart is their ability to readily relinquish electrons, forming positively charged cations within their crystalline atomic structure. These cations are held together by metallic bonds, where the outermost...

ASM International, formerly known as the American Society for Metals, is a professional organization focused on materials science and engineering. It was originally founded in 1913 as the Steel Treaters Club and later became the American Society for Steel Treating in 1920. Over the years, its scope expanded beyond just steel to include all materials,...

Ferrous metals are a category of metals that contain iron as their main constituent element. The most...

Steel is a widely used alloy of iron and carbon, with carbon content typically ranging from 0.2% to...

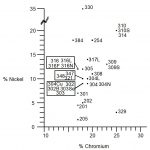

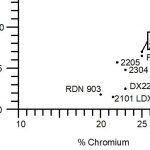

Stainless steel is a versatile material known for its corrosion resistance, high strength, and aesthetic...

This group is the most common type of stainless steel and contains high levels of chromium (usually...

Ferritic stainless steels have little to no nickel. They are magnetic and offer good corrosion resistance,...

Martensitic stainless steels have a moderate chromium content (usually 12-18%) and low nickel. They...

Duplex stainless steels combine the properties of both austenitic and ferritic stainless steels. They...

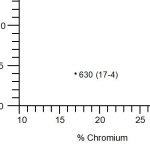

Precipitation-hardening stainless steels contain chromium, nickel, and other alloying elements such...

Tool steel is a type of high-quality carbon and alloy steel that is specifically designed for the production...

Types A2 through A10 are able to harden in an air quench.

Types A8 and A9 are low-carbon, and have...