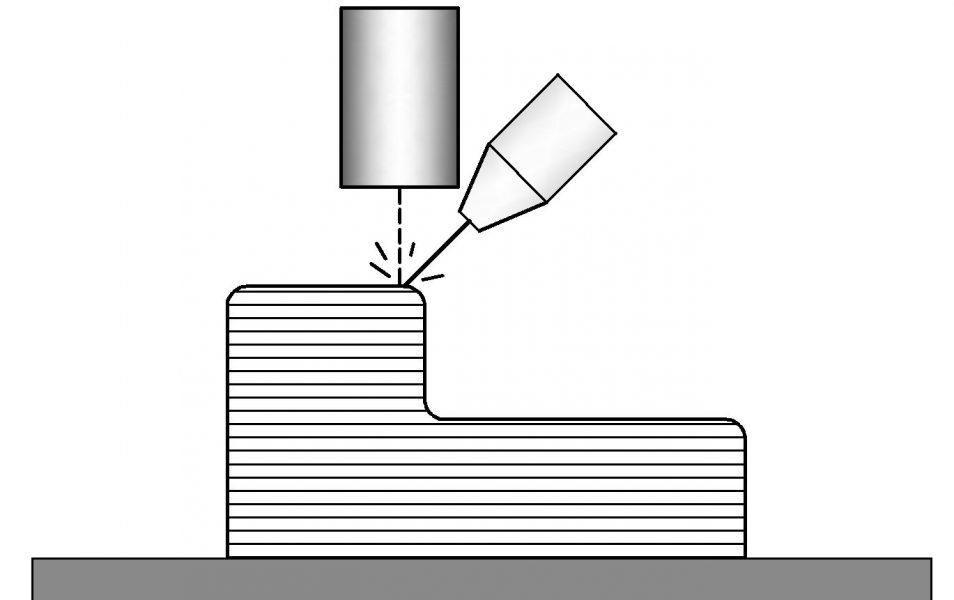

Directed energy deposition is an additive manufacturing process where concentrated heat energy, generated by a focused source like a laser or electron beam, is used to melt and fuse materials as they are being deposited. In simple terms, it involves melting and bonding materials together precisely using a focused heat source during the 3D printing process.

Directed Energy Deposition (DED) is an additive manufacturing process that involves the precise layer-by-layer deposition of material using a concentrated thermal energy source, such as a laser, electron beam, or plasma arc. During DED, a chosen feedstock material, typically in the form of metal powder or wire, is introduced into the deposition area. Simultaneously, the focused heat source is directed onto the material, causing it to melt and fuse with the previously deposited layer. This layering process continues until the entire object is formed. DED is known for its material flexibility, making it suitable for various applications, including aerospace, where it can create intricate and customized components. Additionally, DED’s unique capability for repair and cladding makes it valuable in industries that require maintenance or enhancement of existing parts. Post-processing steps, such as heat treatment or machining, may be necessary to achieve the desired mechanical properties and surface finish. Some DED systems incorporate real-time sensors and monitoring for quality control and optimization.