Hot wire foam cutting is a popular technique used to cut and shape polystyrene foam, also known as expanded polystyrene (EPS), extruded polystyrene (XPS), and other foam materials. The process uses a heated wire to melt and cut through the foam material, allowing for precision cuts and intricate shapes.

Hot wire foam cutting is commonly used in a variety of applications, including model making, sculpture, props and set design, packaging, insulation, and more. In this article, we will provide an introduction to hot wire foam cutting, including its history, equipment, and techniques.

History of Hot Wire Foam Cutting

The origins of hot wire foam cutting can be traced back to the 1950s, when the technique was first used in the aerospace industry to create models and prototypes of aircraft and spacecraft components. The method was also used to create molds for fiberglass components and insulation for refrigeration systems.

Over time, hot wire foam cutting became more accessible and was adopted by hobbyists, artists, and other makers. Today, the technique is widely used in a variety of industries and applications.

Equipment for Hot Wire Foam Cutting

To perform hot wire foam cutting, you will need a few essential pieces of equipment:

- Foam Material: Polystyrene foam sheets, blocks, or shapes are the most commonly used materials for hot wire foam cutting.

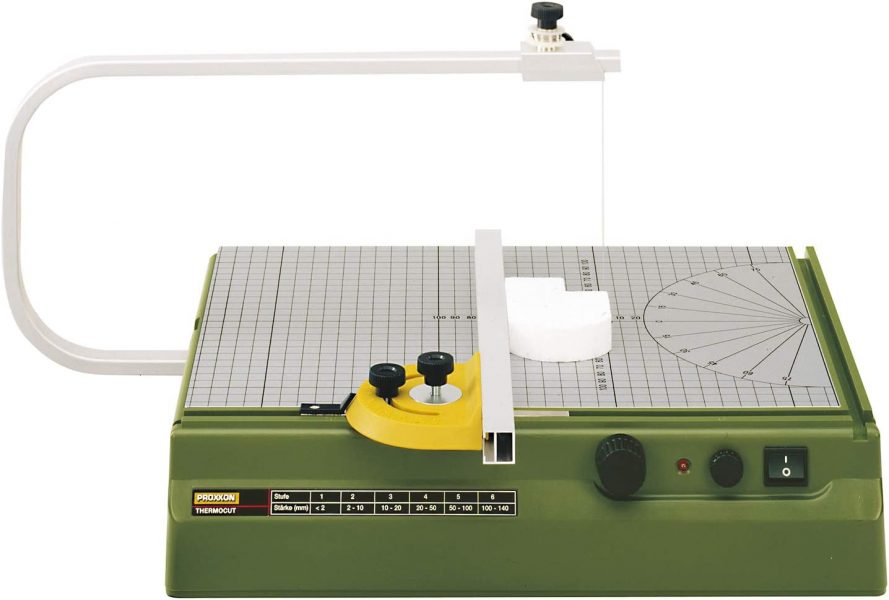

- Hot Wire Foam Cutter: A hot wire foam cutter typically consists of a heated wire or ribbon, a power supply, and a base. The power supply heats the wire, which is then used to cut through the foam material. Hot wire foam cutters are available in a range of sizes and configurations, from handheld cutters to larger table-mounted models.

- Cutting Table: A cutting table provides a flat, stable surface for cutting the foam material. The table can be made from a variety of materials, such as wood, metal, or plastic.

- Templates: Templates are used to guide the hot wire cutter along the desired cutting path. Templates can be made from paper, cardboard, or other materials.

Techniques for Hot Wire Foam Cutting

There are a few different techniques used in hot wire foam cutting, depending on the desired outcome:

- Straight Cuts: Straight cuts are made by guiding the hot wire cutter along a straight line. This technique is used for basic shapes and cuts.

- Contour Cuts: Contour cuts are made by using a template to guide the hot wire cutter along a curved or irregular shape. This technique is used for more intricate shapes and designs.

- Bevel Cuts: Bevel cuts are made by tilting the hot wire cutter at an angle. This technique is used to create angled or tapered edges.

- Sculpting: Sculpting involves using the hot wire cutter to shape and carve the foam material. This technique is commonly used in sculptural and artistic applications.