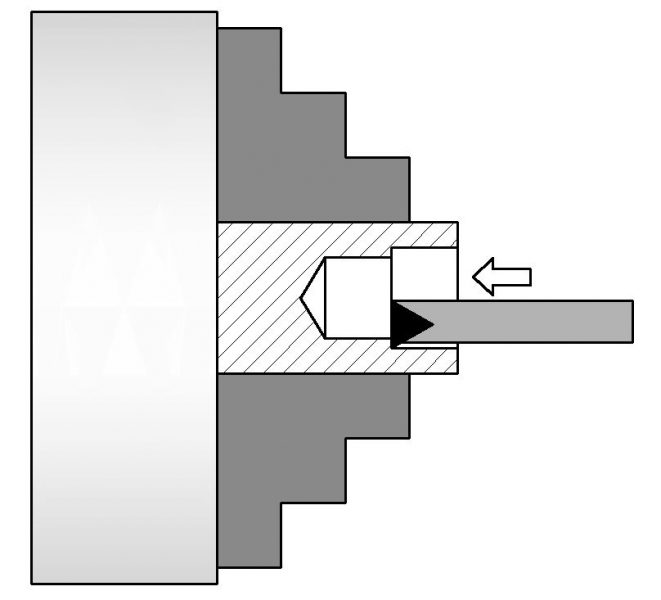

Boring on a lathe is a machining process used to enlarge or refine the internal diameter of a pre-existing hole in a workpiece. It involves the use of a single-point cutting tool mounted on a boring bar, which is inserted into the existing hole. The boring bar is supported by the lathe’s toolpost or tailstock, ensuring stability and precision during the operation. As the workpiece rotates, the boring bar with the cutting tool is fed into the hole, gradually removing material and producing a more accurate, smoother, and often larger-diameter bore. Boring is commonly used to achieve tight tolerances, improve concentricity, and enhance surface finish for applications like creating precision cylindrical holes for bearings or mating parts. The process demands careful control of parameters such as cutting speed, feed rate, and tool geometry to ensure optimal results in terms of dimensional accuracy and surface quality.