Lathe operations encompass a range of machining techniques conducted on a lathe machine, a versatile tool used for shaping, cutting, drilling, and turning various materials like metal, wood, and plastics. These operations include turning, which produces cylindrical shapes, facing for flat surfaces, and taper turning for tapered shapes. Lathes are fundamental in manufacturing and machining processes, offering precision and flexibility in crafting a wide array of components and products.

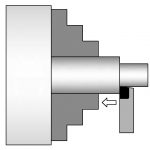

Straight Turning

"Turning" on a lathe refers to the process of removing material from a rotating workpiece to create a cylindrical shape or to achieve specific dimensions and surface finishes. "Straight turning" on a lathe is a term used to describe the process of removing material from a workpiece to create a straight cylindrical shape. In this...

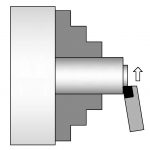

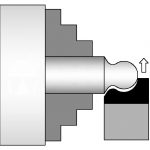

Facing

Facing on a lathe is a machining operation that involves removing material from the end face of a workpiece to create a flat, smooth, and perpendicular surface. The facing process is often used to ensure that the end face of the workpiece is square with the axis of rotation, resulting in a well-defined and accurately...

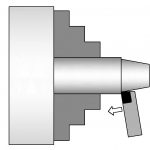

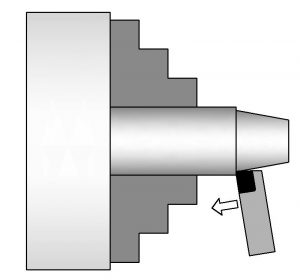

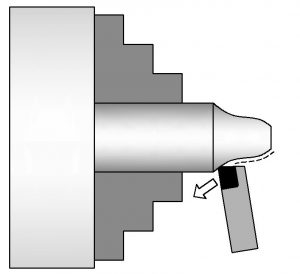

Taper Turning

Taper turning is a machining operation performed on a lathe to create a gradual, regular change in diameter along the length of a cylindrical workpiece. This results in a tapered shape, where one end of the workpiece has a larger diameter than the other. Taper turning is commonly used in applications where a specific angle...

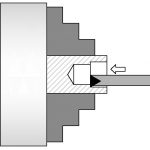

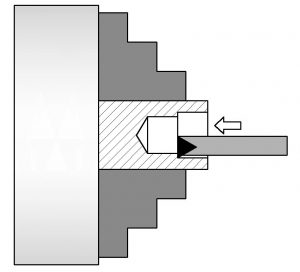

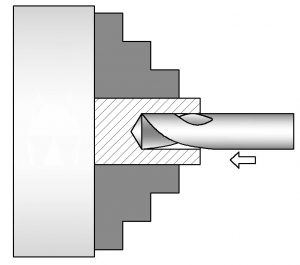

Boring

Boring on a lathe is a machining process used to enlarge or refine the internal diameter of a pre-existing hole in a workpiece. It involves the use of a single-point cutting tool mounted on a boring bar, which is inserted into the existing hole. The boring bar is supported by the lathe's toolpost or tailstock,...

Contour Turning

Contour turning is a machining technique employed to shape workpieces with intricate round, yet non-cylindrical profiles. Unlike conventional straight or taper turning, contour turning involves the precise manipulation of the cutting tool's path to create complex curves, angles, and contours along the length of the workpiece. This technique allows for the production of intricate geometries,...

Form Turning

Form turning is a machining operation that involves using a specially shaped cutting tool to create complex contours, shapes, or profiles on the surface of a workpiece. Unlike traditional turning, where a cylindrical shape is generated, form turning focuses on replicating a specific pre-defined shape onto the workpiece. This process is particularly useful when producing...

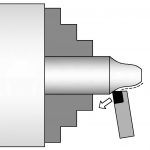

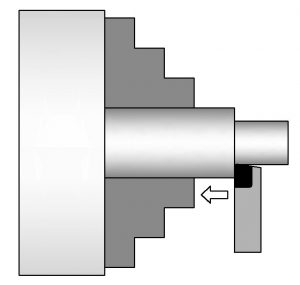

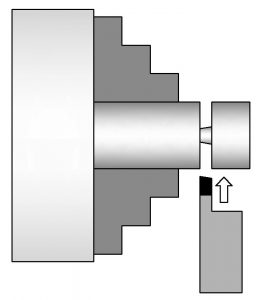

Parting, Parting Off

Parting, also known as parting off, is a lathe machining operation used to cut off a workpiece from a larger stock material. The primary purpose of parting is to separate a finished or semi-finished component from the rest of the material, creating individual pieces with specific lengths. This process is essential for producing individual components...

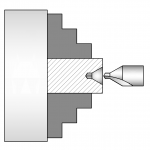

Drilling on a Lathe

Drilling is a fundamental machining process that involves creating precise holes in a workpiece by using a rotating cutting tool relative to a workpiece. When this operation is performed on a lathe using a chuck mounted in the tailstock. As the workpiece rotates, the stationary drill bit is advanced into the material to create a...

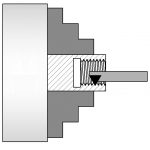

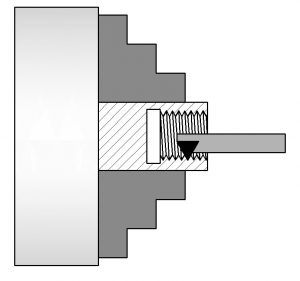

Internal Threading

Internal threading on a lathe is a machining process that involves creating threads within a pre-drilled hole or bore in a workpiece. This operation allows for the integration of screws, bolts, and other threaded components, enabling secure fastening and assembly of parts. Using a specialized tool called a threading insert, the lathe's spindle rotates the...

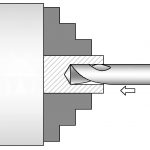

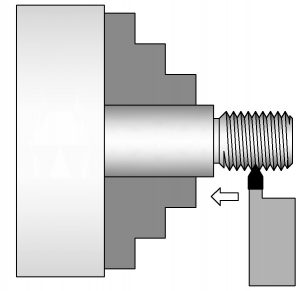

External Threading

External threading on a lathe is a machining technique used to create threads on the outer surface of a workpiece, transforming it into a threaded shaft, bolt, rod, or other components. This process enables the workpiece to be joined with complementary internal threads or fasteners, facilitating secure connections. Utilizing a cutting tool with the appropriate...

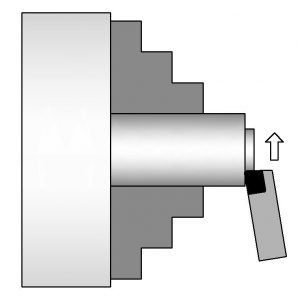

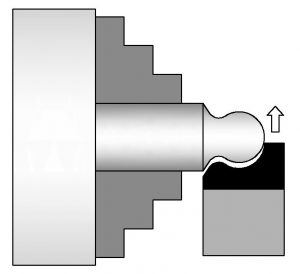

Grooving or Necking

Grooving, also known as necking, is a machining operation performed on a lathe that involves creating a groove or recess along the length of a workpiece. This process is employed to achieve specific design features, such as creating shoulders, grooves, or reduced-diameter sections within a larger workpiece. Using a specialized grooving tool, the lathe's cutting...

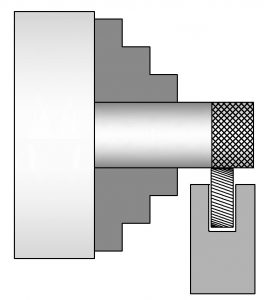

Knurling

Knurling on a lathe is a machining technique employed to create textured patterns on the surface of a workpiece. This process involves using specialized knurling tools that press against the rotating workpiece to impress diamond-shaped or straight-line ridges onto its surface. The result is a tactile and visual enhancement that improves grip, adds aesthetic appeal,...

Straight Turning

"Turning" on a lathe refers to the process of removing material from a rotating workpiece to create...

Facing

Facing on a lathe is a machining operation that involves removing material from the end face of a workpiece...

Taper Turning

Taper turning is a machining operation performed on a lathe to create a gradual, regular change in diameter...

Boring

Boring on a lathe is a machining process used to enlarge or refine the internal diameter of a pre-existing...

Contour Turning

Contour turning is a machining technique employed to shape workpieces with intricate round, yet non-cylindrical...

Form Turning

Form turning is a machining operation that involves using a specially shaped cutting tool to create...

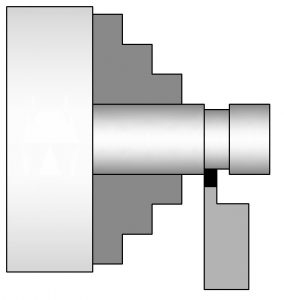

Parting, Parting Off

Parting, also known as parting off, is a lathe machining operation used to cut off a workpiece from...

Drilling on a Lathe

Drilling is a fundamental machining process that involves creating precise holes in a workpiece by using...

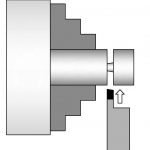

Center Drilling

Center drilling is a machining operation often performed on a lathe or other machining equipment. The...

Internal Threading

Internal threading on a lathe is a machining process that involves creating threads within a pre-drilled...