A small manufacturing company want to manufacture small fuel tanks for the hobby remote control (RC) market by a process known as rotational molding.

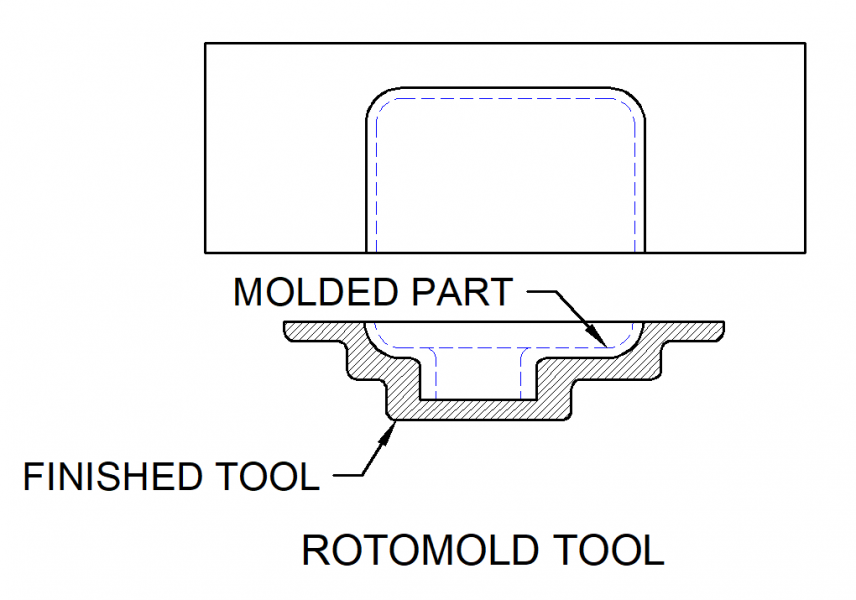

Design a roto-mold for this tank: M40 FUEL TANK to be made from cast aluminum. The mold can be any number of pieces, but the fewer the better. A draft can be added to surfaces where required.

What are some of the challenges? What dimensions would be difficult to hold and why? How would you handle the hole?

Note: This project can be extended by designing the casting patterns for the mold, or programming the mold design to be milled by a CNC machine.