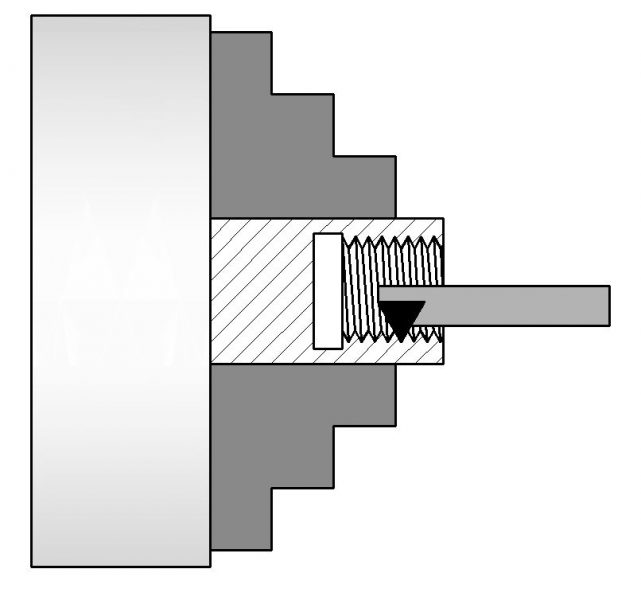

Internal threading on a lathe is a machining process that involves creating threads within a pre-drilled hole or bore in a workpiece. This operation allows for the integration of screws, bolts, and other threaded components, enabling secure fastening and assembly of parts. Using a specialized tool called a threading insert, the lathe’s spindle rotates the workpiece while the threading tool is fed into the hole at a specific pitch to gradually form the internal threads. The tool’s geometry corresponds to the desired thread profile, ensuring precise alignment and proper engagement with external threads. Threading on a lathe demands meticulous attention to parameters like thread pitch, cutting speed, and depth of cut to achieve accurate thread dimensions and a smooth surface finish. This process is widely utilized in industries such as manufacturing, automotive, aerospace, and more, where the creation of internal threads is critical for functional and structural components.