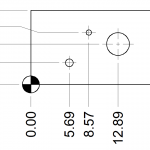

Dimensioning is a crucial aspect of engineering drawings, which plays an essential role in communicating design specifications and requirements to manufacturers, engineers, and other stakeholders. Essentially, dimensioning refers to the process of specifying the exact size, shape, and location of different parts and features on an engineering drawing.

Dimensioning is vital in the engineering industry as it ensures that the final product meets the required standards and specifications. It helps to minimize errors and inaccuracies during the manufacturing process, thereby reducing the risk of costly mistakes and delays. Additionally, it enables engineers and manufacturers to ensure that the final product meets the customer’s expectations, which is critical in today’s competitive market.

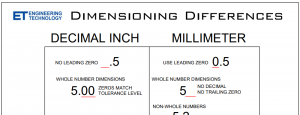

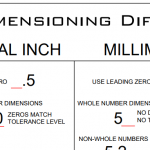

To ensure that engineering drawings are dimensioned correctly, various industry standards must be followed. For example, the American Society of Mechanical Engineers (ASME) has developed a set of guidelines that outline the proper practices for dimensioning engineering drawings. These guidelines include specifying the appropriate units of measurement, ensuring clear and concise labeling, and avoiding ambiguity or confusion when dimensioning features.

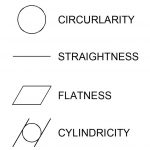

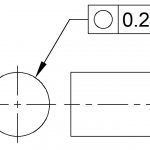

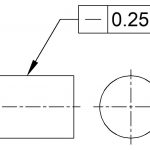

Another important aspect of dimensioning is tolerancing, which involves specifying the allowable deviation or variation from the specified dimensions. Tolerancing is crucial in ensuring that the final product is functional and reliable, as it allows for the natural variation that can occur during the manufacturing process.