A lathe is a versatile machine tool used for shaping, cutting, and drilling various materials. Its key components include the bed, serving as the machine’s base; the headstock, containing the spindle for workpiece rotation; the tailstock, offering support for the other end of the workpiece; and the carriage, which houses the tool post and cross-slide for precise cutting. The tool post holds the cutting tool, while the feed mechanism controls the tool’s movement along the workpiece’s surface. Lathes also feature spindle speed control, power sources, and essential safety features. These components and characteristics enable lathes to perform a wide range of turning operations on materials like metal, wood, and plastics, making them essential tools in machining and manufacturing.

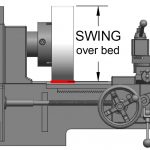

Swing

Swing on a lathe refers to the pivotal measurement that defines the machine's capability to handle different workpiece diameters. It plays a crucial role in selecting the right lathe for specific machining tasks. The key swing measurements include: Swing Over the Bed This measurement represents the distance from the lathe's spindle centerline to the inner...

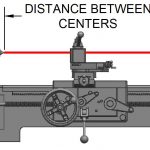

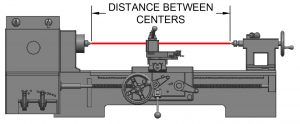

Distance Between Centers

distance between centers on a lathe is the maximum length of a workpiece that can be held and machined on the lathe. It is a critical specification when selecting a lathe for a specific project, ensuring that the lathe can accommodate the desired workpiece length and meet the machining requirements.

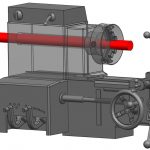

Spindle Bore Diameter

The spindle bore diameter, often simply referred to as the bore diameter, is a critical specification of a lathe machine. It represents the inside diameter of the hole or opening through the spindle, which is the rotating component responsible for holding and securing the workpiece during machining operations. The spindle bore diameter specifies the size...

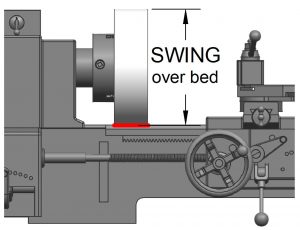

Swing

Swing on a lathe refers to the pivotal measurement that defines the machine's capability to handle different...

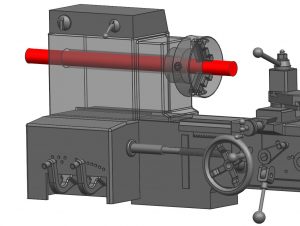

Distance Between Centers

distance between centers on a lathe is the maximum length of a workpiece that can be held and machined...

Spindle Bore Diameter

The spindle bore diameter, often simply referred to as the bore diameter, is a critical specification...