Tool and cutter grinding is a specialized form of grinding used to create and sharpen cutting tools such as drills, end mills, and milling cutters. It is an essential process in the manufacturing industry, as the quality of the tools produced affects the quality and efficiency of the finished products.

The goal of tool and cutter grinding is to create tools with precise geometries and cutting edges that are capable of producing accurate and consistent cuts. This is achieved by grinding away material from the tool’s cutting edges until the desired shape and edge geometry are achieved.

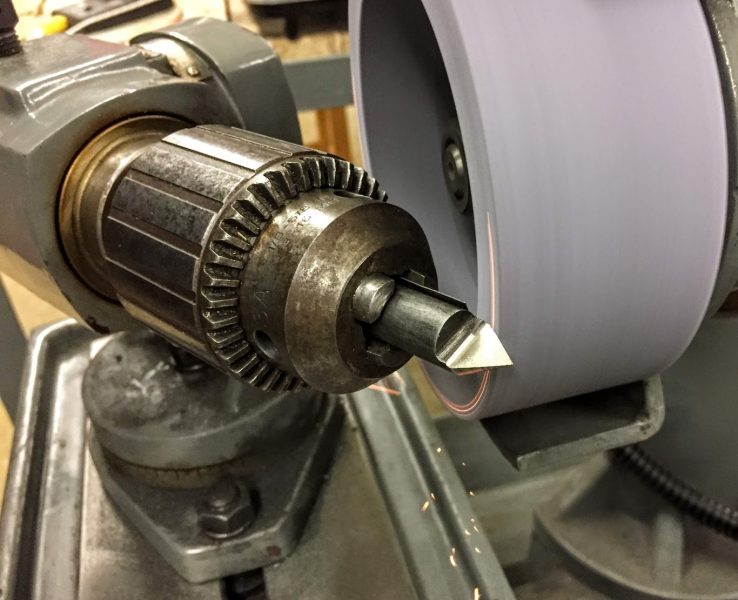

During the grinding process, the cutting tool is held in a specially designed fixture that allows it to be moved across the grinding wheel in precise increments. The grinding wheel removes material from the cutting edge of the tool, creating the desired shape and edge geometry.

After the grinding process is complete, the tool is inspected to ensure that it meets the desired specifications. This may involve using specialized measuring tools, such as a toolmaker’s microscope or a digital micrometer, to measure the tool’s dimensions and geometry.

Tool and cutter grinding requires a high level of skill and expertise, as even small errors in the grinding process can result in a tool that is unusable or of poor quality. For this reason, it is typically performed by highly trained professionals who have extensive experience in tool and cutter grinding.