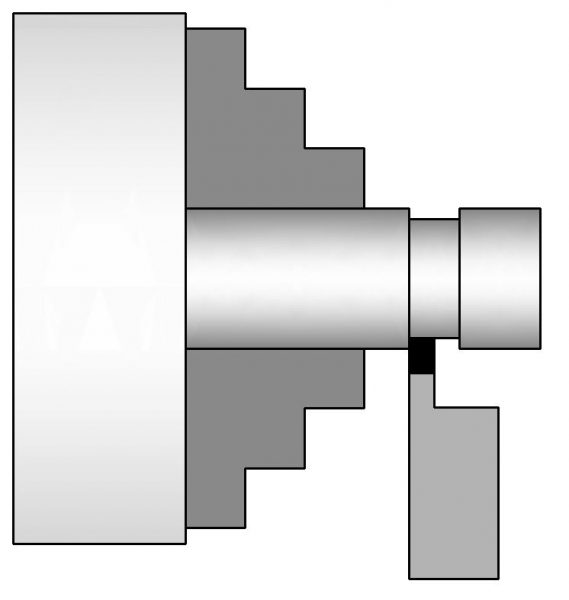

Grooving, also known as necking, is a machining operation performed on a lathe that involves creating a groove or recess along the length of a workpiece. This process is employed to achieve specific design features, such as creating shoulders, grooves, or reduced-diameter sections within a larger workpiece. Using a specialized grooving tool, the lathe’s cutting tool is fed radially into the workpiece to remove material and form the desired groove. Grooving can serve functional purposes like providing clearance for components or facilitating a secure fit between parts. It can also be used for decorative or aesthetic reasons. Precision in tool positioning, cutting depth, and feed rate is essential to achieve accurate groove dimensions and a smooth surface finish.