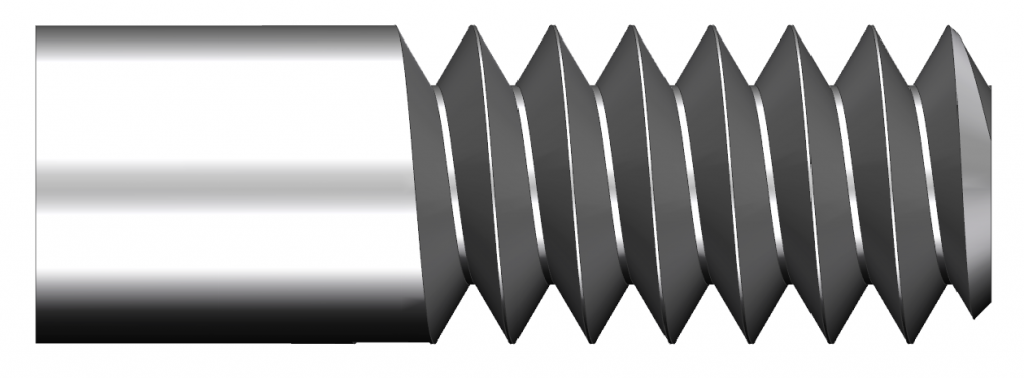

Screw threads are an essential component in a wide range of mechanical systems. They are used to fasten two or more objects together, transmit rotational motion and power, and help convert rotary motion into linear motion. Threads are formed by cutting or rolling a helical ridge onto the surface of a cylinder or screw.

Thread manufacturing is the process of creating screw threads on screws, bolts, and other threaded components. There are several methods used to manufacture screw threads, including cutting, rolling, and grinding. Cutting methods involve using a single-point cutting tool to create threads by removing material from the surface of a cylindrical blank. Rolling methods involve using a set of thread rolling dies to compress and form the threads onto the surface of a cylindrical blank. Grinding methods involve using a grinding wheel to remove material and create the threads.

The choice of thread manufacturing method depends on the material being used, the desired thread form, and the production volume. For high-volume production, rolling and grinding methods are often preferred due to their efficiency and consistency. For small-volume production, cutting methods are often preferred due to their versatility and low cost. Regardless of the manufacturing method used, the resulting screw threads must meet specific dimensional and functional requirements to ensure proper fit and performance in the final assembly.