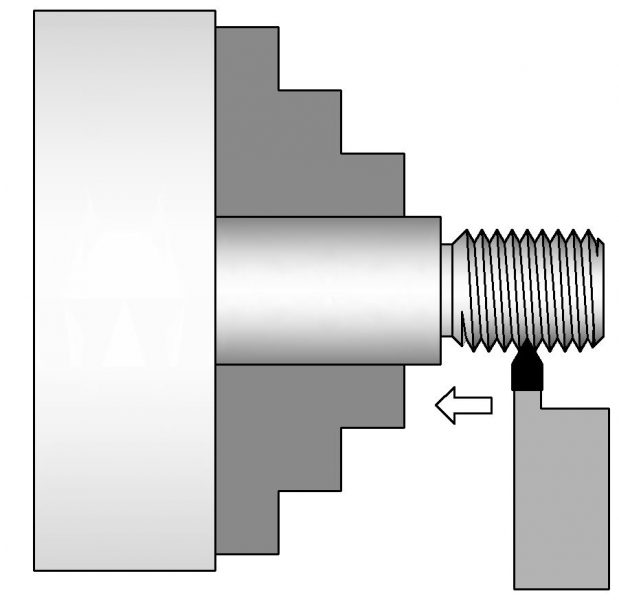

External threading on a lathe is a machining technique used to create threads on the outer surface of a workpiece, transforming it into a threaded shaft, bolt, rod, or other components. This process enables the workpiece to be joined with complementary internal threads or fasteners, facilitating secure connections. Utilizing a cutting tool with the appropriate threading profile, the workpiece is rotated by the lathe’s spindle while the cutting tool is fed along the length of the workpiece at a precise pitch. As the cutting tool engages with the workpiece’s surface, it removes material, gradually forming the external threads. Achieving accurate external threads requires careful control of variables such as thread pitch, cutting speed, and depth of cut to ensure correct dimensions and a smooth finish.