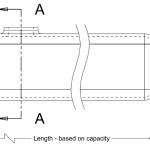

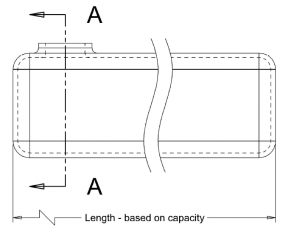

Scenario A small company manufactures plastic tanks suitable for a variety of purposes including fuel tanks for the hobby remote control (RC) market. In addition to their standard line of fuel tanks, they want to offer fuel tanks in custom configurations. You can see an example of one of their tanks here: Fuel Tank. CUSTOM-FUEL-TANK-SPECIFICATION-SHEETDownload...

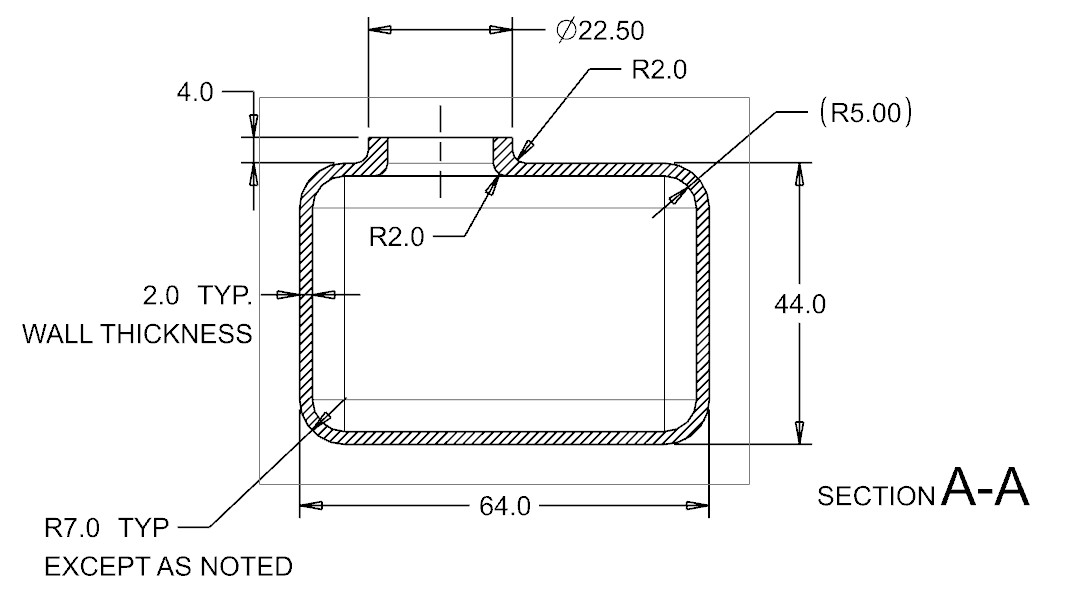

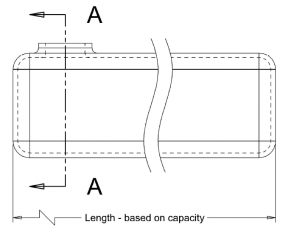

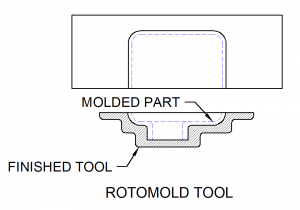

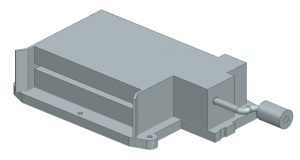

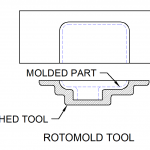

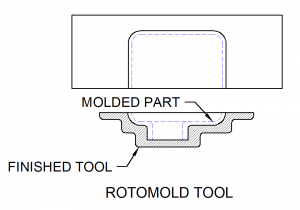

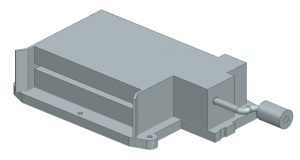

A small manufacturing company want to manufacture small fuel tanks for the hobby remote control (RC) market by a process known as rotational molding. Design a roto-mold for this tank: M40 FUEL TANK to be made from cast aluminum. The mold can be any number of pieces, but the fewer the better. A draft can...

(in progress Fall 2023) The Carnivore 212 is an near clone of the famous Harbor Freight Predator 212 which is a near clone of the Honda GX160. It is used as a case study for manufacturing engineering technology courses at the University of Memphis. References Predator 212 Manual

Design a bike repair stand that can be clamped to a workbench that has a thickness between 1.5 and 2.0 inches. The stand should include a clamp. Design the clamp to be cast aluminum. The clamp mechanism can be toggle or screw variety. The the stand frame should be made of tubular steel. The stand...

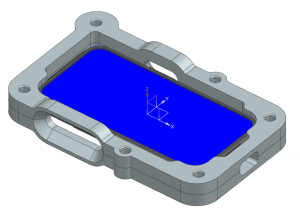

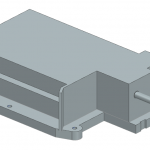

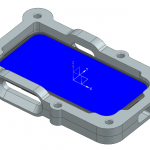

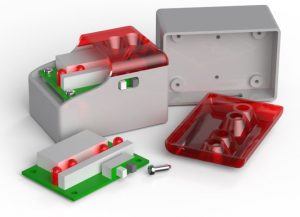

Design a plastic housing for the Kitronik rear bike light kit. The battery holder and the PC board should be mounted firmly in place. You may use the screws provided or design a snap-fit retaining feature. Note: The screws included in the zip file require a hole diameter of 2.25 mm. The housing should include...

This 30 note music box can be the basis for a variety of engineering technology projects. 3D and 2D files are available below. There is also a 15 note box that is less expensive. Reverse engineer the box design (more photos) Design processes and tooling for individual components Design a housing for the movement. Be...

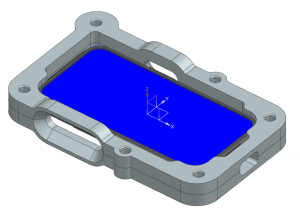

Design a case that can hold your phone. Provide attachment points for however you use your phone (boom attachment, microphone, lights, handles, etc). Provide a means of assembly and disassembly. Be sure to include a way to access buttons and charging and other cables. 3D print your design and demonstrate that it works the way...

Guitar pedalboard made of 16 gauge hot-rolled steel sheet and 1 inch square tube. Full-Layout-Not-full-scaleDownload Pedalboard-Full-Scale-on-PaperDownload Pedal-board-10-degree-side-viewDownload

Scenario

A small company manufactures plastic tanks suitable for a variety of purposes including...

A small manufacturing company want to manufacture small fuel tanks for the hobby remote control (RC)...

(in progress Fall 2023) The Carnivore 212 is an near clone of the famous Harbor Freight Predator 212...

Item Description Quantity 1 Bolt, Flange 6 2 Cover, Head 1 3 Asm., Head Cover 1 4 Tube, Breather...

Design a bike repair stand that can be clamped to a workbench that has a thickness between 1.5 and 2.0...

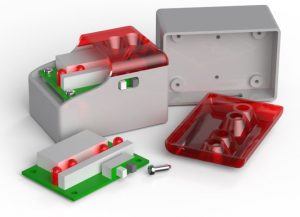

Design a plastic housing for the Kitronik rear bike light kit . The battery holder and the PC board...

This 30 note music box can be the basis for a variety of engineering technology projects. 3D and 2D...

Design a case that can hold your phone. Provide attachment points for however you use your phone (boom...

Guitar pedalboard made of 16 gauge hot-rolled steel sheet and 1 inch square tube.

Full-Layout-Not-full-scale...