Shearing is a fundamental manufacturing process within sheet metal fabrication, serving as a primary method for cutting and shaping flat metal sheets. This process involves the use of shearing machines equipped with sharp blades, where the upper blade descends against the lower blade to cut through the sheet material. Shearing is particularly effective for straight-line...

Punching is a prominent process in sheet metal fabrication that involves the use of a punch and die to create holes, slots, or other geometric features in sheet metal. This versatile technique is widely employed in the production of sheet metal components across diverse industries, including automotive, electronics, and construction. In the punching process, the...

Bending is a process in sheet metal fabrication that imparts shape and structure to flat sheets, transforming them into three-dimensional components. This technique generally involves the use of a press brake, where the sheet metal is positioned between a punch and a die. The press brake applies force to the sheet, causing it to deform...

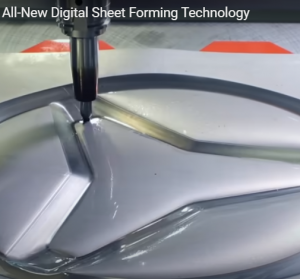

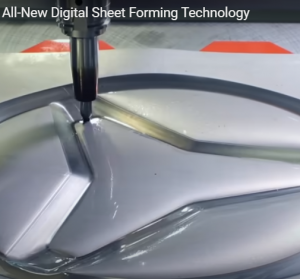

Principles of Incremental Sheet Forming Incremental Sheet Forming is a versatile manufacturing process that involves the gradual deformation of a metal sheet using a localized tool. Unlike traditional forming processes that utilize dies and molds, ISF employs a CNC-controlled tool that moves incrementally, shaping the metal sheet layer by layer. This layer-wise approach gives engineers...

Embossing, is a process used to create raised or sunken designs or patterns on the surface of a metal sheet. It involves using specialized tooling and presses to deform the metal, resulting in a three-dimensional pattern. Embossing is often employed for decorative or functional purposes, such as adding texture, branding, or strengthening the metal sheet....

Spinning, also known as spin forming or metal spinning, is a specialized sheet metal forming process used to create cylindrical or conical shapes from flat sheets or pre-formed blanks. This technique is particularly valuable for producing symmetrical components such as domes, cones, and cylindrical shells. Metal spinning is commonly employed in industries such as aerospace,...

Stamping is a fundamental sheet metal forming process widely employed in manufacturing industries such as automotive and appliances. This process involves shaping metal sheets into desired forms and configurations using specialized dies and punches. The metal sheet is placed between the dies, and pressure is applied to deform the material, creating the desired shape. Stamping...

Shearing is a fundamental manufacturing process within sheet metal fabrication, serving as a primary...

Right angle shearing is a specialized form of shearing in sheet metal fabrication that focuses on creating...

Slitting is a crucial process in sheet metal fabrication, specifically applied to sheet metal coils....

Punching is a prominent process in sheet metal fabrication that involves the use of a punch and die...

Blanking is a crucial sheet metal fabrication process that involves cutting a flat sheet to create a...

Turret punch presses are specialized machines used in sheet metal fabrication for precise punching and...

Bending is a process in sheet metal fabrication that imparts shape and structure to flat sheets, transforming...

Sheet metal brakes are tools used for bending and shaping sheet metal into desired forms. The primary...

Automated bending centers represent advanced machinery in metal fabrication, designed for high-efficiency...

A press brake is a machine tool used in sheet metal fabrication, designed for precise bending and forming...