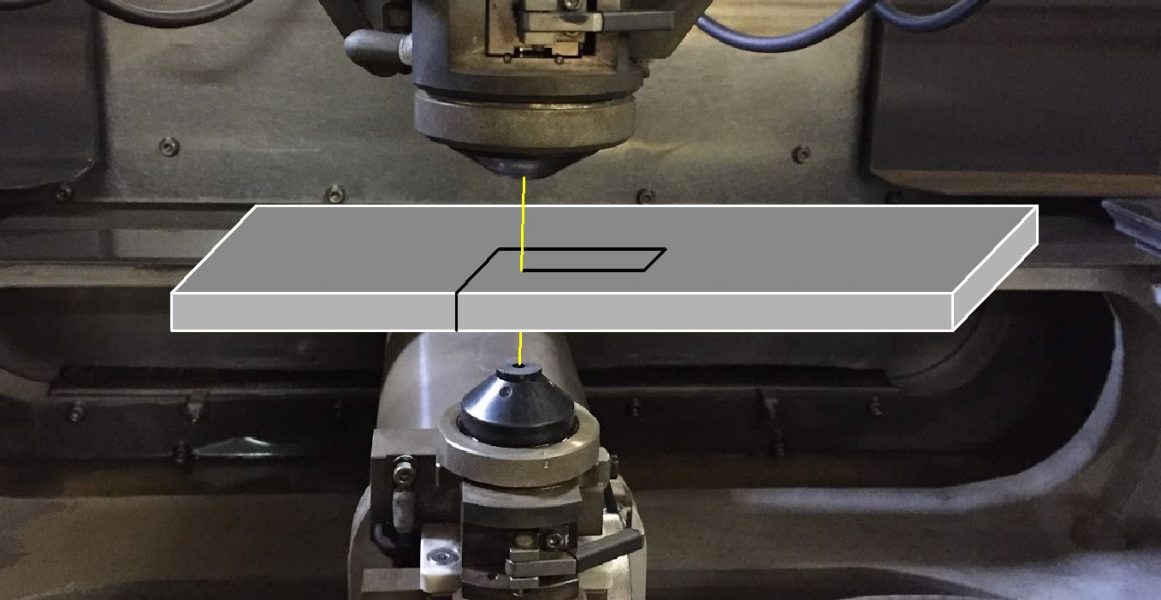

Wire Electrical Discharge Machining (Wire EDM) is a specialized machining technique that employs a slender, electrically conductive wire as the tool electrode. This thin wire is submerged in a dielectric fluid, usually deionized water, which serves multiple purposes during the process, including cooling, debris removal, and providing a medium for electrical discharges to occur.

In Wire EDM, a workpiece made of an electrically conductive material is shaped or cut with precision. This is achieved by applying an electrical voltage between the wire electrode and the workpiece, causing controlled electrical discharges or sparks to jump across the small gap between them. These sparks generate intense heat, melting or vaporizing small portions of both the wire and the workpiece.

As the process continues, material is gradually eroded from the workpiece, and the wire electrode is continuously fed to create intricate and precise cuts. Wire EDM is particularly valued for its ability to create complex and fine-detailed shapes in conductive materials, making it indispensable in industries such as aerospace, toolmaking, mold production, and precision engineering. Its CNC-controlled system enables the machining of intricate profiles and contours with exceptional accuracy.