Extrusion is a common manufacturing process used to create continuous lengths of products with a fixed cross-sectional profile. The process is commonly used to create plastic pipes, tubes, profiles, and sheeting. Extrusion is a continuous process that uses a plastic resin or compound, which is melted and then forced through a die to form the desired shape. The extruded product can be cut to length, coiled, or further processed.

The extrusion process starts with the plastic resin or compound being fed into a hopper. The hopper feeds the material into a screw or ram that moves the material forward, compresses it, and melts it as it moves through the barrel of the extruder. The barrel is heated to a temperature that is high enough to melt the plastic but not so high that it degrades. The screw or ram generates a shearing force on the plastic, which increases the surface area and promotes even heating. Much of the heat involved in the process is generated by the shearing action of the screw.

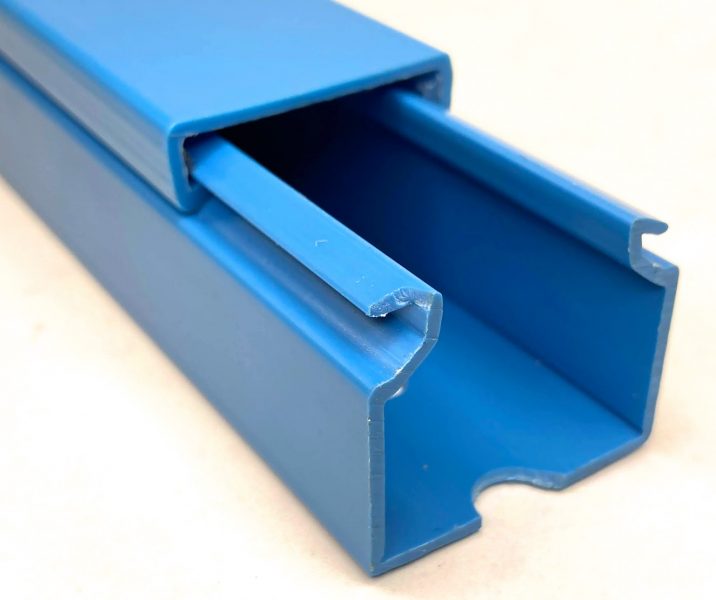

Once the plastic is melted, it is forced through a die, which shapes the plastic into the desired cross-sectional profile. The die can be designed to create a range of shapes, from simple round or square shapes to more complex profiles with multiple internal channels or features. The die can also be designed to impart texture or surface patterns (such as ribs) onto the plastic.

As the plastic exits the die, it is cooled to solidify and stabilize the shape. Cooling is generally achieved by passing the extrudate through a water bath. Once the plastic has been cooled and solidified, it can be further processed through cutting, punching, or other finishing operations.

Extrusion is a versatile and efficient process that can produce high volumes of plastic products at a relatively low cost. It is commonly used in industries such as construction, automotive, and packaging. By adjusting the formulation of the plastic resin or compound, manufacturers can create products with a range of physical and mechanical properties, such as flexibility, stiffness, and impact resistance. Extruded plastic products can also be customized with various colors, textures, and finishes to meet specific design requirements.