Composite materials, known for their exceptional strength-to-weight ratio, thermal stability, and corrosion resistance, have revolutionized numerous industries, from aerospace to automotive and beyond. However, the production of these advanced materials presents a set of complex challenges that manufacturers must navigate to harness their full potential.

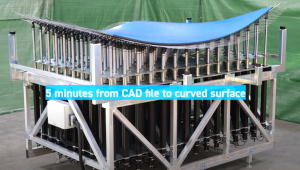

Tooling Design and Fabrication

Tooling, the molds and dies used to shape composite materials, is a critical element in the manufacturing process. The design and fabrication of these tools demand meticulous attention to detail. Composite materials, often consisting of layers of fibers or particles embedded in a matrix, require precisely crafted molds to ensure uniform distribution of reinforcement and matrix materials. The challenge lies in creating tooling that can withstand the curing temperatures and pressures necessary for composite consolidation without distorting or degrading the final product’s quality. Moreover, the complexity of some composite geometries demands sophisticated tooling solutions that can be time-consuming and expensive to develop.

Material Selection and Compatibility

Selecting the right combination of reinforcement fibers and matrix materials is crucial to achieving desired mechanical and thermal properties in composites. The challenge arises from the need to balance factors such as strength, stiffness, weight, and cost while ensuring compatibility between the chosen materials. Mismatched coefficients of thermal expansion between the reinforcement and matrix can lead to delamination and reduced mechanical performance over time, highlighting the importance of comprehensive material testing and characterization. Moreover, the variability in material properties, even within the same batch, requires stringent quality control measures to maintain consistency in the final product.

Manufacturing Procedures and Quality Control

The manufacturing processes for composites can be intricate, involving precise layering of materials, vacuum infusion, compression molding, and more. Achieving uniform distribution of reinforcement and matrix materials throughout the composite structure is essential to guarantee consistent mechanical performance. However, variations in manual layup, resin infusion rates, and curing conditions can lead to defects such as voids, resin-rich areas, or insufficient bonding between layers. Detecting and rectifying such defects necessitate sophisticated inspection techniques and rigorous quality control protocols.

Environmental Impact and Sustainability

While composites offer numerous advantages, their production often involves energy-intensive processes and the use of non-renewable resources. Moreover, the disposal of composite waste and end-of-life products poses environmental challenges. As the industry evolves, finding sustainable alternatives in both material sourcing and waste management becomes imperative to reduce the ecological footprint of composite manufacturing.

In conclusion, manufacturing composite materials is a multidimensional endeavor that demands a deep understanding of tooling design, material compatibility, and precise procedural execution. Overcoming these challenges requires a collaborative effort between materials scientists, engineers, and manufacturers. As technology advances, innovations in tooling fabrication, material science, and quality control techniques will continue to pave the way for more efficient and sustainable production of these remarkable materials.