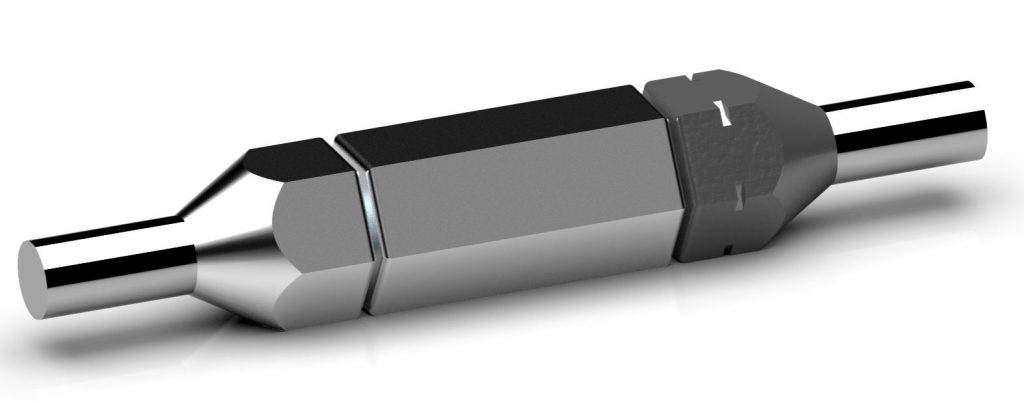

A go-no go gauge, also known as a no-go/go gauge, is a specialized type of gauge used in manufacturing and quality control to quickly and accurately determine whether a manufactured part or product meets the specified tolerances and dimensional requirements.

The “go” side of the gauge consists of a set of features, such as holes, pins, or slots, that are precisely machined to the upper acceptable limit of the part’s dimensions. When the part being inspected fits smoothly and correctly into these features, it is within the acceptable range and is considered to have passed the inspection.

The “no-go” side of the gauge includes features machined to the lower acceptable limit of the part’s dimensions. If the part fits into these features, it means the part’s dimensions are smaller than the acceptable range, and it is rejected.

The go-no go gauge provides a quick and binary assessment of whether a part meets the specified tolerances, without the need for detailed measurements. It simplifies the quality control process by clearly indicating whether a part is acceptable or not. This is especially valuable in high-volume manufacturing environments, where speed and efficiency are essential.

Go-no go gauges are commonly used in various industries, including automotive, aerospace, and manufacturing, to ensure that parts are produced to precise specifications and meet quality standards.