Fillets and rounds play an important role in mechanical design and manufacturing. By smoothing transitions between surfaces and reducing stress concentrations, they help to improve the strength and durability of mechanical components. Additionally, by providing a more aesthetically pleasing appearance, they also help to enhance the overall look and feel of a product.

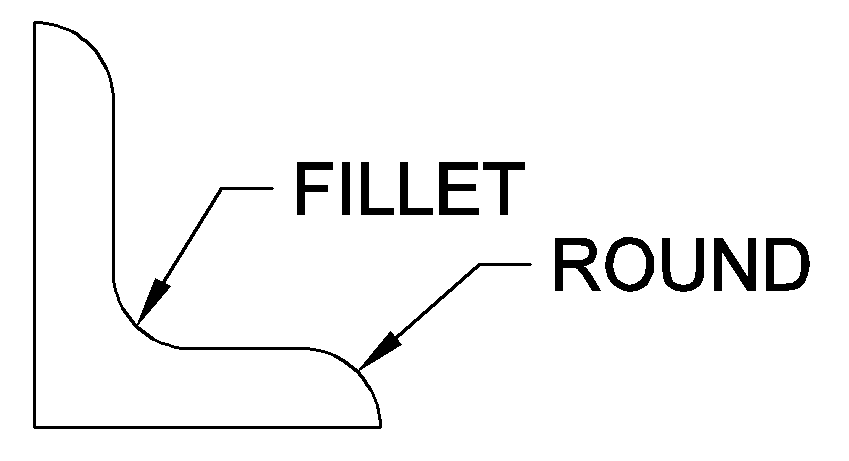

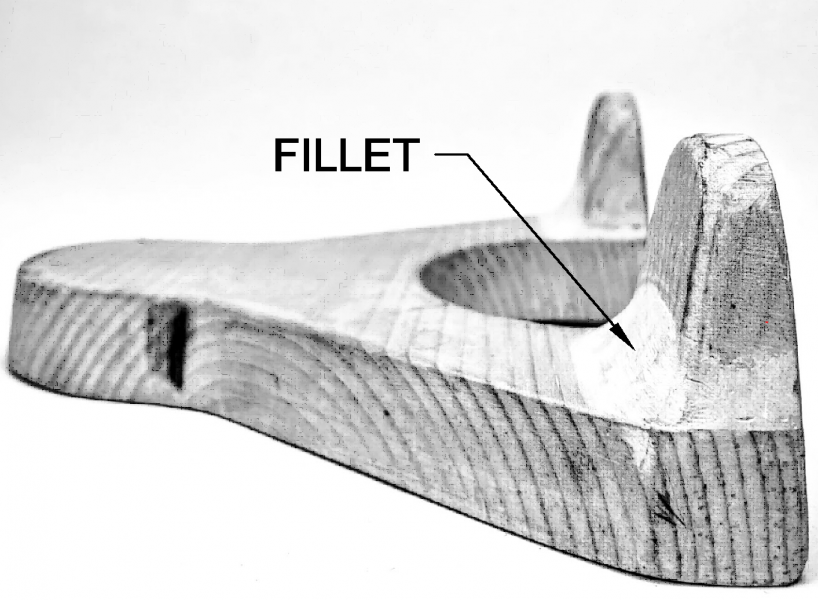

A fillet is a rounded corner that is used to transition between two internal flat surfaces in a mechanical component. The fillet helps to reduce stress concentrations at the corner and improve the overall strength of the component. By rounding the corners, the fillet also helps to reduce the risk of cracking and breaking, making the component more durable.

A round, on the other hand, is a circular cross-section that is used to connect external surfaces. A round helps to reduce stress concentrations and improve the overall strength of the component, just as a fillet does. Rounds are often used in fasteners, such as screws and bolts, to provide a smooth transition between the threads and the shank of the fastener.

Specifying Fillets and Rounds

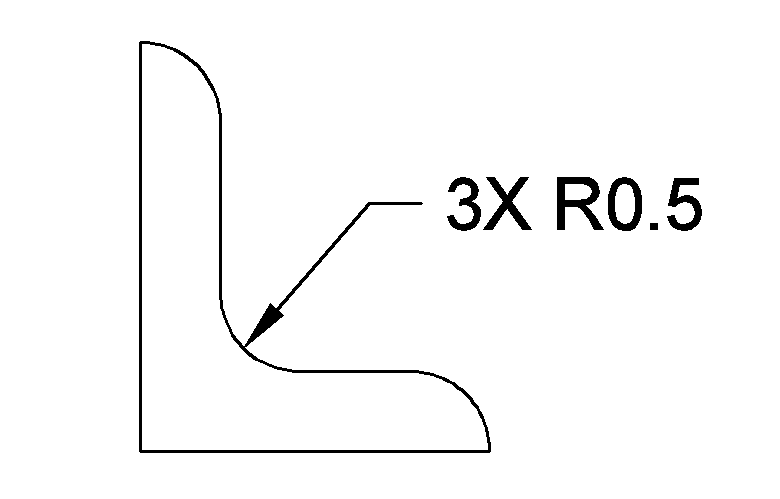

In engineering drawings, fillets and rounds are typically specified using dimensional tolerances and geometrical tolerance symbols. Fillets and rounds are specified using the “Radius” symbol, “R”. The radius value is given next to the symbol. For example, a 0.5 inch fillet radius would be represented as: “R0.5”.

Unless specified, the location of the center of both fillets and rounds is a radius away from each of the surfaces they are joining. That is, they are tangent to the surface.