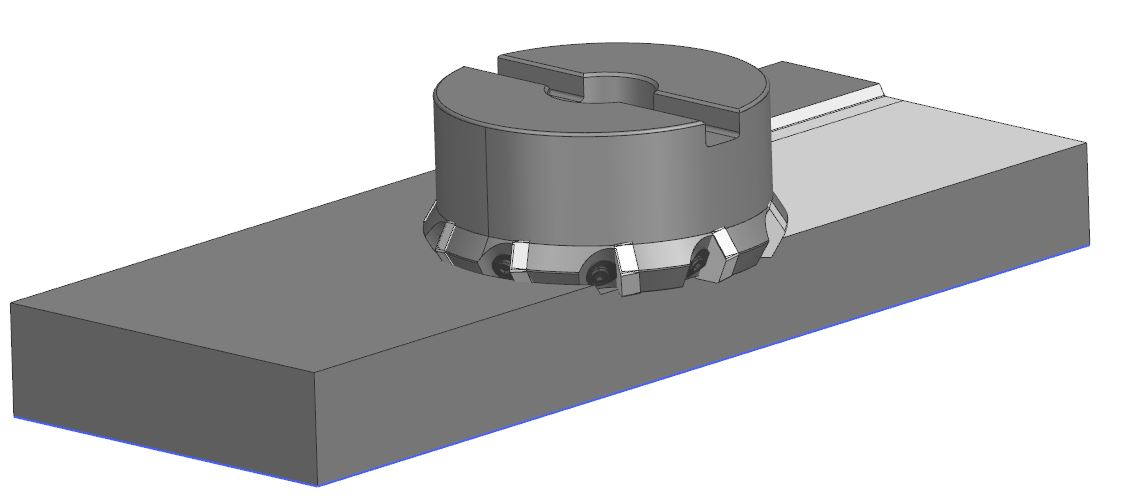

Face milling is a machining process employed in manufacturing and metalworking to create flat surfaces on a workpiece. This milling technique involves the use of a milling cutter with multiple cutting edges, known as inserts, arranged on the cutter’s face. The cutter is mounted on a milling machine or machining center, and as it rotates, it makes contact with the workpiece.

The primary objective of face milling is to remove material from the top surface of the workpiece, achieving a flat and smooth finish. The cutting action occurs along a plane parallel to the workpiece’s top surface. This process is highly effective for tasks such as leveling and squaring a part, removing rough or uneven surfaces, and producing precise, flat surfaces required for various applications in industries like automotive, aerospace, and manufacturing.

Face milling is capable of producing both large flat areas and intricate contours, depending on the shape and arrangement of the cutting inserts on the milling cutter. The choice of milling parameters, including cutting speed, feed rate, and depth of cut, can be adjusted to optimize the machining process for specific workpiece materials and desired surface finishes. Face milling plays a crucial role in the fabrication of components and parts used in various mechanical systems and structures.