Laser beam cutting is a process that uses a highly focused laser beam to cut through a variety of materials, including metals, plastics, and composites. The process has become increasingly popular in recent years due to its ability to produce precise, intricate cuts with a high level of accuracy. In this article, we’ll explore the basics of laser beam cutting, including the different types of laser cutting systems, the materials that can be cut, and the advantages of this process over traditional cutting methods.

Types of Laser Cutting Systems

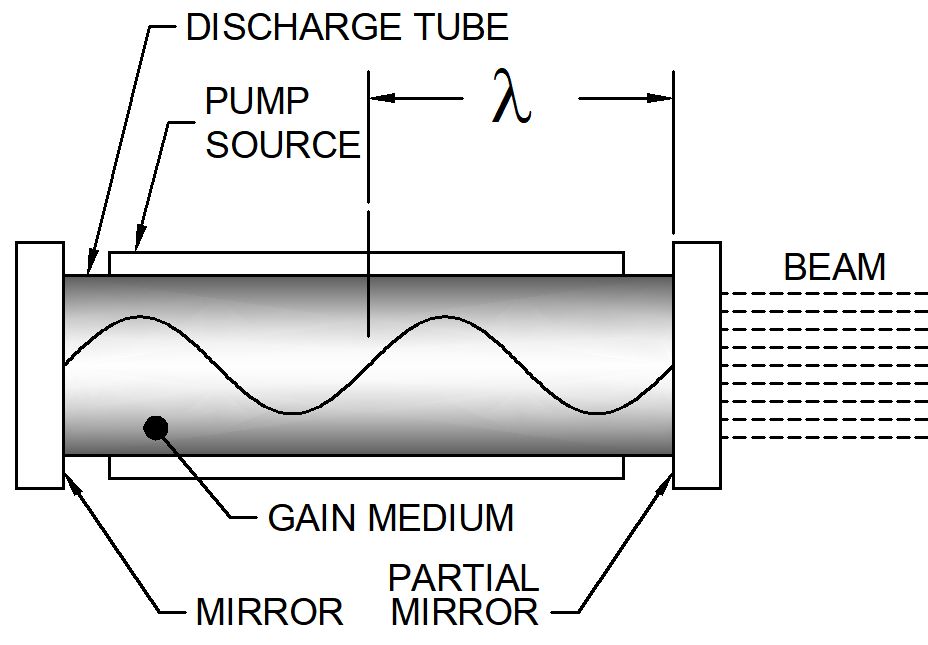

There are two main types of laser cutting systems: CO2 lasers and fiber lasers. CO2 lasers, which use a gas mixture of carbon dioxide, nitrogen, and helium, are ideal for cutting thicker materials and are typically used in heavy-duty industrial applications. Fiber lasers, on the other hand, use a doped fiber to generate the laser beam, making them more compact and energy-efficient than CO2 lasers. Fiber lasers are often used for cutting thinner materials and for applications that require a higher level of precision.

Materials that Can be Cut

Laser beam cutting can be used to cut a wide variety of materials, including:

- Metals: Laser beam cutting is particularly effective for cutting metals such as steel, aluminum, and stainless steel. The high precision and accuracy of the laser beam allows for intricate cuts and precise edges.

- Plastics: Laser beam cutting is used to cut a wide variety of plastics, including PVC, polycarbonate, and Acrylic. The process is ideal for cutting intricate shapes and designs with a high level of accuracy.

- Composites: Laser beam cutting is used to cut composite materials, including fiberglass and carbon fiber. The process is ideal for cutting complex shapes and patterns with a high level of precision.

Advantages of Laser Beam Cutting

Laser beam cutting offers several advantages over traditional cutting methods, including:

- Precision: Laser beam cutting provides precise cuts with a high level of accuracy, making it ideal for applications that require tight tolerances.

- Speed: The high speed of the laser beam allows for faster cutting times, making laser beam cutting a more efficient process than traditional cutting methods.

- Versatility: Laser beam cutting can be used to cut a wide variety of materials, making it a versatile process for a wide range of applications.

- Clean cuts: Laser beam cutting produces clean, precise cuts without creating any burrs or other defects.

Laser beam cutting is a precise, efficient, and versatile process that has become increasingly popular in recent years. Whether you need to cut metal, plastic, or composite materials, laser beam cutting is an ideal solution that offers precise cuts and a high level of accuracy.

References

“Laser Cutting – Wikipedia.” Wikipedia, the Free Encyclopedia, Wikimedia Foundation, Inc., 17 Mar. 2004, https://en.wikipedia.org/wiki/Laser_cutting.