Machining is a manufacturing process that involves removing material from a workpiece to create a desired shape and size. Machining processes are used to create a wide range of precision components for various applications in industries such as automotive, aerospace, medical, and more. Machining processes include turning, milling, drilling, grinding, and more. These processes are performed using a variety of tools and machines such as lathes, milling machines, drills, grinders, and others. Machining requires skilled operators who can read engineering drawings and use various tools and machines to create high-quality parts with tight tolerances. It is a critical process in modern manufacturing and plays a vital role in the production of a wide range of products.

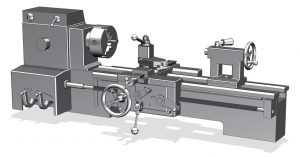

Machine Tools

Machine tools are a fundamental cornerstone of modern manufacturing and engineering, playing a pivotal role in shaping raw materials into finished products with precision and efficiency. These highly specialized devices, ranging from lathes and milling machines to CNC systems, enable the transformation of various materials, such as metal, plastic, and wood, into intricate components and...

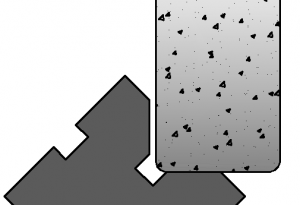

Grinding and Abrasive Machining

Grinding and Abrasive MachiningWater Jet Cutting Surface Grinding Handheld Grinding Tool and Cutter Grinding Creep Feed Grinding Media Blasting Shot Blasting and Peening Vapor Blasting Abrasive machining is a group of manufacturing processes that involve using abrasive particles to remove material from a workpiece. The process can be used to produce precision parts with tight...

Lathes and Turning Operations

Lathes and Turning OperationsLathe Components and Configurations Swing Distance Between Centers Spindle Bore Diameter Lathe Operations Straight Turning Facing Taper Turning Boring Contour Turning Form Turning Parting, Parting Off Drilling on a Lathe Center Drilling Internal Threading External Threading Grooving or Necking Knurling

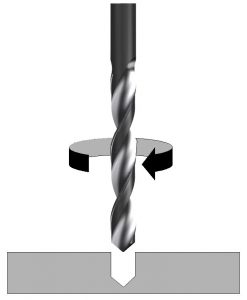

Drilling and Holemaking

Drilling is one of many ways of making holes in a workpiece. Drilling is a fundamental machining operation that involves creating holes in a workpiece using a rotating cutting tool called a drill bit. This process is widely utilized across various industries to generate holes of specific diameters and depths in different materials, ranging from...

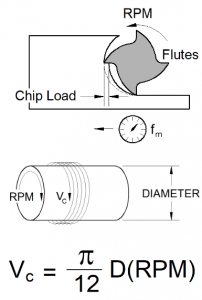

Machining Parameters

Machining parameters are the various settings and factors that affect the performance of machining processes. These parameters include cutting speed, feed rate, depth of cut, and coolant type, among others. The selection of appropriate machining parameters is critical to achieving optimal results in terms of part quality, tool life, and production efficiency. Machining parameters depend...

Sawing

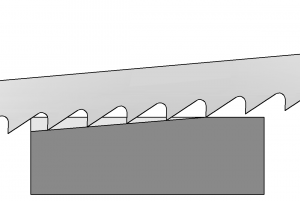

Sawing is a mechanical cutting process that involves using a saw or similar cutting tool to remove material from a workpiece by creating a separation along a predefined path or kerf. Sawing is a versatile and widely used method for cutting various materials, including wood, metal, plastics, and composites.

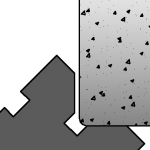

Shapers and Planers

Shapers and planers are both machine tools used for machining flat and contoured surfaces on workpieces. These machines are less common in modern manufacturing due to their slower cutting speeds compared to other machining methods. Shapers A shaper is a machine tool designed for precision machining of flat or contoured surfaces on workpieces. It operates...

Machine Tools

Machine tools are a fundamental cornerstone of modern manufacturing and engineering, playing a pivotal...

Milling Operations, Tools, and Strategies

The correct selection of tools, workholding, cutting parameters, and milling techniques can significantly...

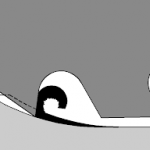

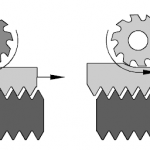

Climb Milling And Conventional Milling

In climb milling the rotation of the tool pulls the work off of the lead screw.

Climb milling and...

Right and Left Handed End Mills

The main differences between a right-handed and left-handed end mill is the direction in which they...

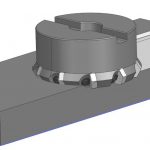

Boring Head - Mill

Boring is a machining process used to enlarge an existing hole to a precise diameter and surface finish....

Face Milling

Face milling is a machining process employed in manufacturing and metalworking to create flat surfaces...

Contour Milling

Contour milling is a machining process employed to shape and create complex, contoured surfaces on a...

Grinding and Abrasive Machining

Abrasive machining is a group of manufacturing processes that involve using abrasive particles...

Water Jet Cutting

Water jet cutting is a manufacturing process that utilizes a high-pressure jet of water to cut through...