Continuous casting, also known as strand casting, is a manufacturing process used to produce large quantities of metal products in a continuous, uninterrupted manner. It is one of the most efficient and cost-effective methods of producing metal products, and is used extensively in the production of steel, aluminum, and other metals.

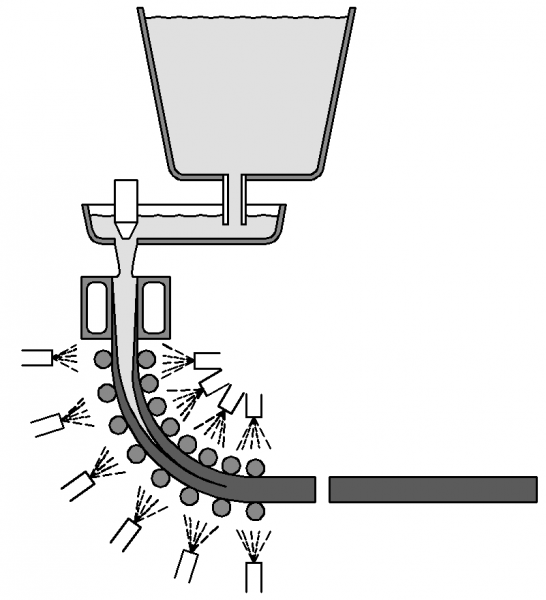

The basic principle of continuous casting involves pouring molten metal into a mold and allowing it to solidify into a continuously cast strand. The strand is then cooled, typically by water or air, before being cut into the desired length for further processing.

The continuous casting process has several stages, including the preparation of the molten metal, the casting of the strand, and the cooling and cutting of the finished product. The preparation stage involves melting the metal in a furnace and refining it to the desired composition. The casting stage involves pouring the molten metal into the mold and allowing it to solidify into a continuous strand. The cooling stage involves rapidly cooling the strand to a temperature that is low enough to allow for handling, typically by water or air. The cutting stage involves cutting the continuous strand into the desired length for further processing.

One of the key advantages of continuous casting is its high efficiency and low cost compared to other casting methods. Because the casting process is continuous, it is possible to produce large quantities of metal products in a short period of time. Additionally, the continuous casting process results in uniform products with consistent quality, reducing the need for additional processing and improving the overall efficiency of the manufacturing process.

Continuous casting has been widely adopted in the metal industry, and is used to produce a wide range of metal products, including billets, blooms, slabs, and rounds. In conclusion, continuous casting is an important and efficient method for producing metal products, and its widespread adoption has greatly improved the efficiency and cost-effectiveness of the metal manufacturing industry.