Swing on a lathe refers to the pivotal measurement that defines the machine’s capability to handle different workpiece diameters. It plays a crucial role in selecting the right lathe for specific machining tasks. The key swing measurements include:

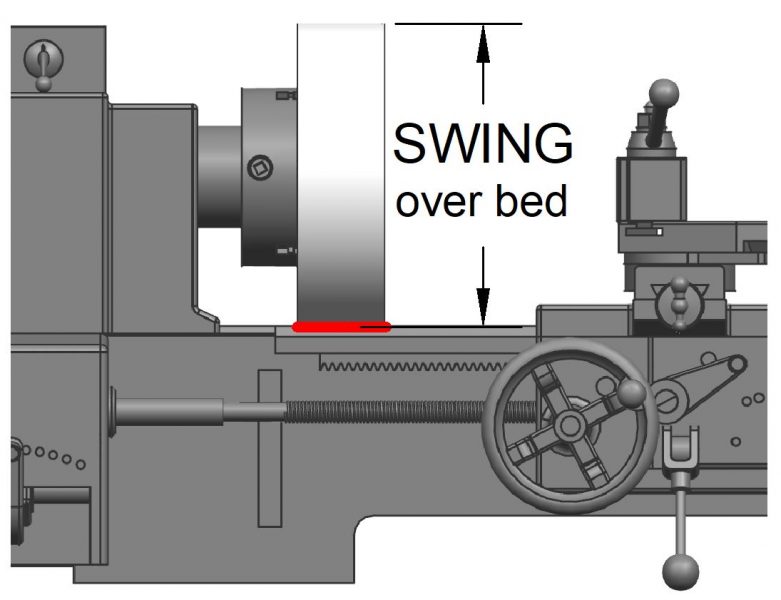

Swing Over the Bed

This measurement represents the distance from the lathe’s spindle centerline to the inner surface of the bed, multiplied by two. It signifies the maximum diameter of a workpiece that can be turned on the lathe without any obstructions. For most turning operations, this measurement is central in determining the lathe’s capacity.

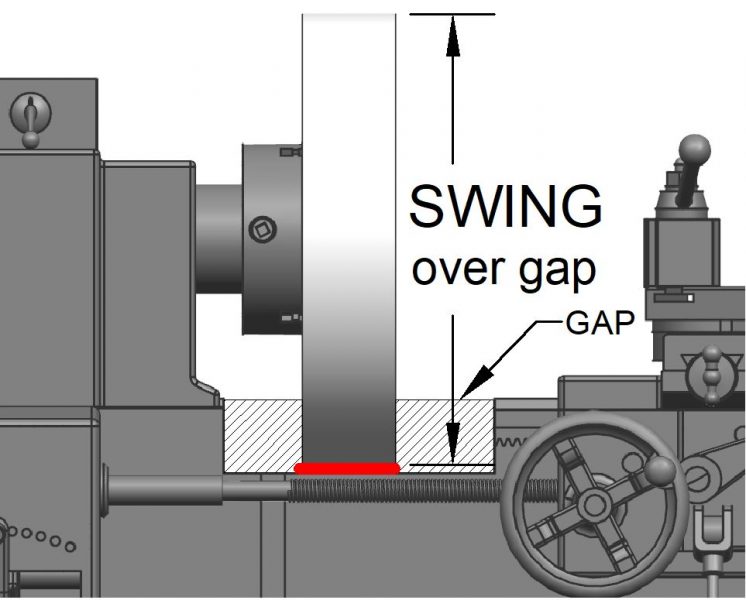

Swing Over the Gap

In the case of gap bed lathes, there is a removable section in the bed known as the gap. Swing over the gap specifies the largest workpiece diameter that can be turned when the gap section is removed. This measurement is particularly useful when dealing with oversized workpieces that wouldn’t fit within the confines of the bed.

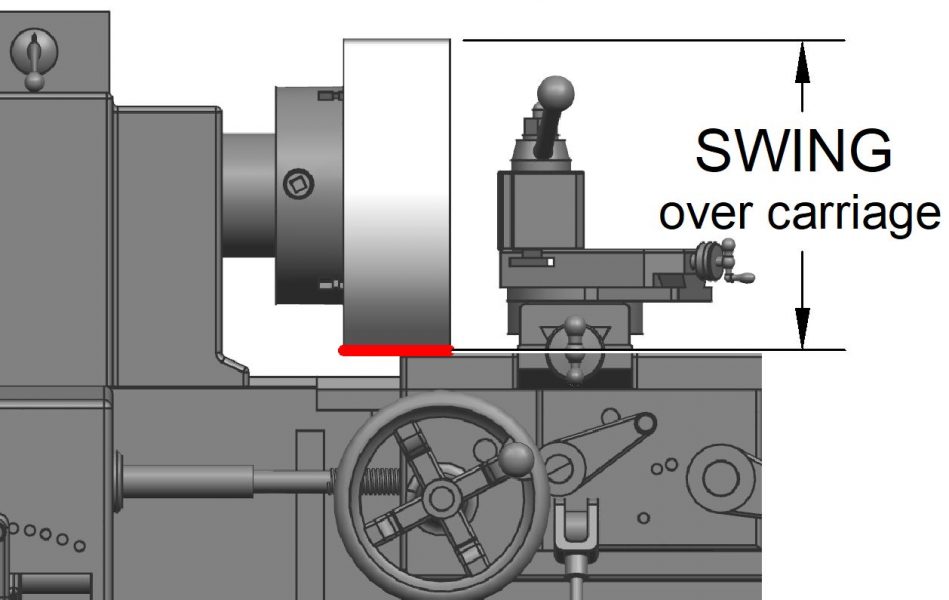

Swing Over the Carriage

Swing over the carriage represents the maximum diameter of a workpiece that can be turned when the carriage, which houses the tool post and cutting tool, is in its rearmost position. This measurement is significant when you need to work on larger workpieces and need the tool carriage to clear the workpiece’s diameter.

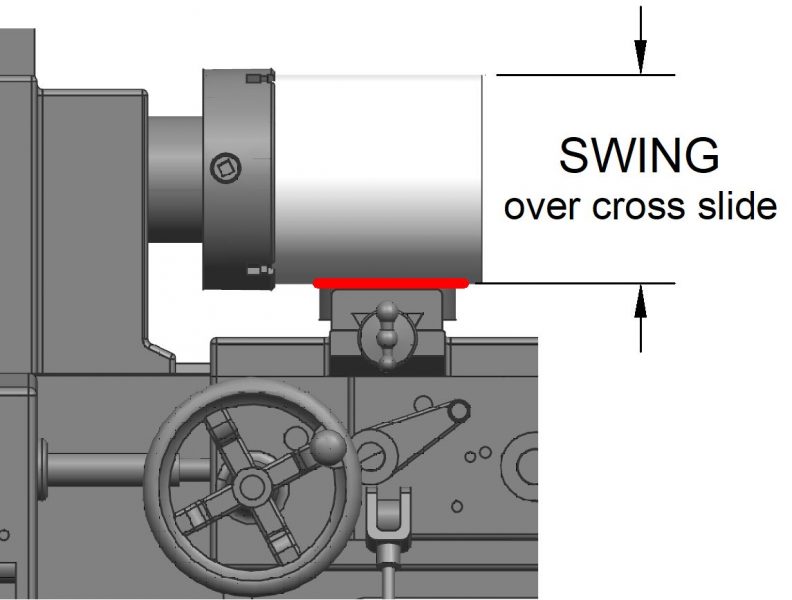

Swing Over the Cross Slide

The swing over the cross slide indicates the maximum diameter of a workpiece that can be turned when the cross slide, which moves perpendicular to the lathe’s axis, is positioned at its extreme rearward position. This measurement is valuable for operations requiring lateral movement of the cutting tool across the workpiece’s surface.

These swing measurements collectively provide essential information for matching the lathe’s capacity to the requirements of specific machining tasks. Whether it’s regular turning operations, accommodating oversized workpieces using the gap, or ensuring tool clearance with the carriage and cross slide positions, understanding swing is fundamental for effective lathe operation and workpiece selection.