Grinding and Abrasive Machining

Abrasive machining is a group of manufacturing processes that involve using abrasive particles to remove material from a workpiece. The process can be used to produce precision parts with tight tolerances and surface finish requirements, as well as to remove surface imperfections and prepare surfaces for further processing. There are two main types of abrasive machining: free abrasive machining and bonded abrasive machining.

Free abrasive machining involves using loose abrasive particles to remove material from the workpiece. The abrasive particles are typically mixed with a fluid, such as water or oil, and are sprayed onto the workpiece using a nozzle. The workpiece is then moved back and forth over the abrasive stream to remove material from the surface. Free abrasive machining is commonly used for applications such as polishing, honing, and lapping.

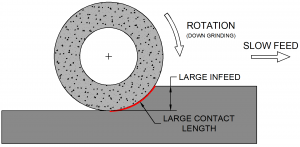

Bonded abrasive machining, on the other hand, involves using abrasive particles that are mounted onto a tool, such as a grinding wheel or a sanding belt. The tool is then brought into contact with the workpiece and rotated or moved back and forth to remove material from the surface. Bonded abrasive machining is commonly used for applications such as grinding, sanding, and cutting. Boded abrasives may be mounted onto shafts, arbors, or other toolholding elements.

Both free and bonded abrasive machining processes require careful selection of the abrasive material and the operating parameters to achieve the desired results. The choice of abrasive material depends on factors such as the material being machined, the desired surface finish, and the required material removal rate. Common abrasive materials include aluminum oxide, silicon carbide, and diamond.

Abrasive machining is widely used in manufacturing industries to produce precision parts with tight tolerances and surface finish requirements. It is commonly used in industries such as aerospace, automotive, medical, and electronics, where precision and surface finish quality are critical. With its ability to remove material in a highly controlled manner, abrasive machining is an essential process in the production of precision machine parts, ensuring optimal performance and functionality.