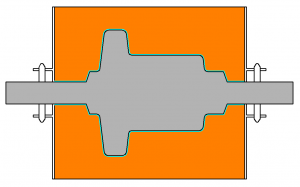

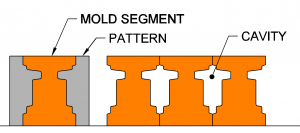

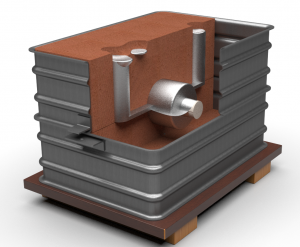

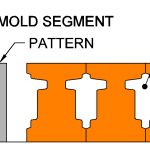

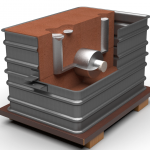

In sand casting, a pattern of the desired part is created, and then a mold is made by packing sand around the pattern. The mold is then separated into two halves, and the pattern is removed. The two halves of the mold are then reassembled, and the liquid metal is poured into the mold. After the metal has solidified, the mold is broken open, and the part is removed.

Sand casting is an appropriate manufacturing process when the part to be produced is relatively large, has a complex shape, and requires a rough surface finish. Sand casting is also an economical process for producing small to medium-sized parts in large quantities. Additionally, sand casting is well suited for producing parts made of ferrous and non-ferrous metals, including iron, steel, aluminum, and bronze.

One of the advantages of sand casting is that it can produce parts with a relatively low cost, as the mold can be made from readily available materials, such as sand and clay. However, sand casting also has some disadvantages, including the relatively long lead time required to make the mold, the requirement for manual labor to pack the sand around the pattern, and the limited surface finish that can be achieved with the process. Despite these limitations, sand casting remains a popular and widely used manufacturing process.