Shielded Metal Arc Welding (SMAW), commonly known as stick welding, is a manual arc welding process that employs a consumable electrode coated in a flux material. During the welding process, an electric arc is established between the tip of the electrode and the workpiece. The intense heat generated by the arc melts both the electrode...

Flux-Core Arc Welding (FCAW) is a welding process that utilizes a continuous, tubular wire electrode filled with flux. Unlike traditional welding methods that rely on external shielding gas, FCAW generates its shielding gas from the flux within the electrode when it melts. An electric arc is formed between the wire electrode and the workpiece, creating...

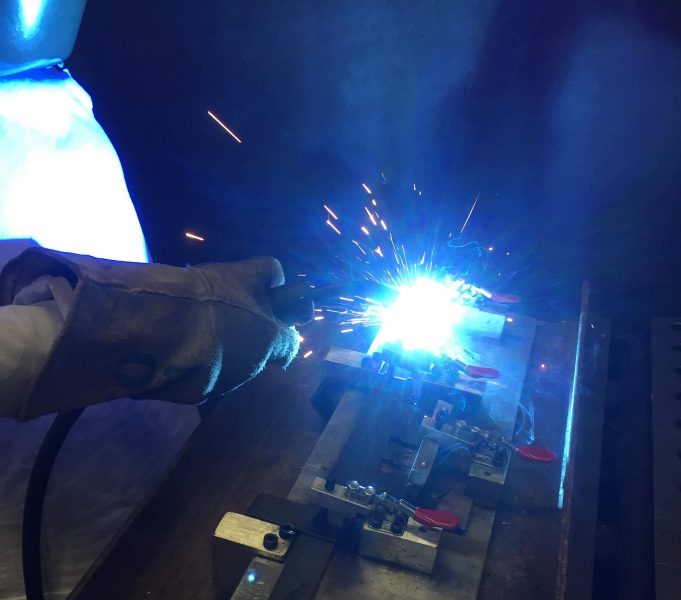

Gas Metal Arc Welding (GMAW), often referred to as MIG (Metal Inert Gas) or MAG (Metal Active Gas) welding, is a versatile and widely used welding process. In GMAW, a continuous wire electrode is fed through a welding gun, where an electric arc is created between the wire and the workpiece. Simultaneously, a shielding gas,...

Submerged Arc Welding (SAW) is an automated welding process known for its efficiency and suitability for welding thick materials. In SAW, a continuous wire electrode is fed mechanically into the weld joint, while a granular flux material blankets the arc and the welding area. The electric arc generates intense heat, melting both the wire electrode...

Arc Stud Welding (SW) is a specialized welding process designed primarily for fastening metal studs to a base material, often in construction and industrial applications. In SW, a metal stud with one end chamfered or otherwise pre-shaped is placed against the workpiece, and an arc is initiated between the stud and the work surface. The...

Shielded Metal Arc Welding (SMAW), commonly known as stick welding, is a manual arc welding process...

Flux-Core Arc Welding (FCAW) is a welding process that utilizes a continuous, tubular wire electrode...

Gas Metal Arc Welding (GMAW), often referred to as MIG (Metal Inert Gas) or MAG (Metal Active Gas) welding,...

Submerged Arc Welding (SAW) is an automated welding process known for its efficiency and suitability...

Arc Stud Welding (SW) is a specialized welding process designed primarily for fastening metal studs...