Forming Processes

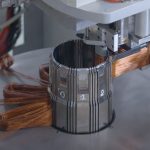

Forming is a category of manufacturing processes that involves the deformation of a raw material into a desired shape or form. These processes often involve the application of external forces such as bending, stretching, compressing, or twisting. Forming processes are widely used in industries such as automotive, aerospace, construction, and electronics to produce a wide range of products with complex shapes and sizes. The advantages of forming processes include the ability to produce parts with high strength and durability, high production rates, and the ability to work with a wide range of materials, including metals, polymers, and composites.

There are several types of forming processes, including sheet metal forming, forging, and extrusion. Each process has its own unique set of advantages and limitations, and the selection of the most appropriate process depends on the material properties, desired product shape, and production volume. Overall, forming processes play a critical role in modern manufacturing and are essential for the production of a wide range of products.