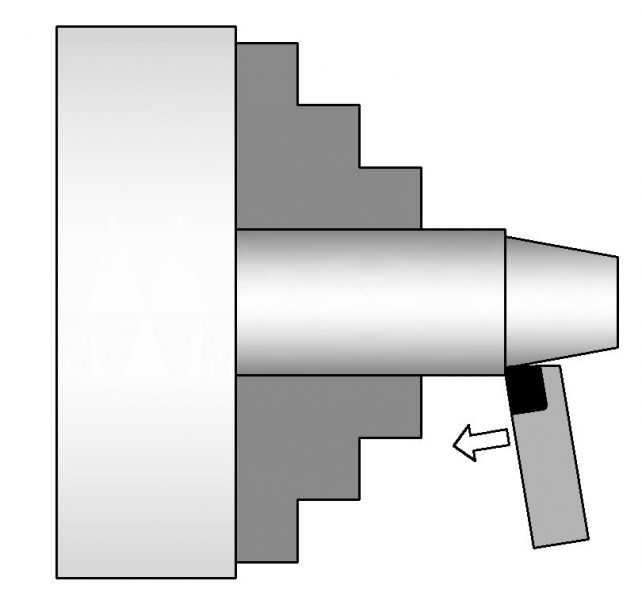

Taper turning is a machining operation performed on a lathe to create a gradual, regular change in diameter along the length of a cylindrical workpiece. This results in a tapered shape, where one end of the workpiece has a larger diameter than the other. Taper turning is commonly used in applications where a specific angle or taper is required, such as in creating conical shapes, tapered shafts, and various types of tooling.

The process of taper turning involves adjusting the angle of the cutting tool travel relative to the axis of rotation of the workpiece. The angle at which the tool is moved determines the rate of taper, with a steeper angle creating a more rapid change in diameter and a shallower angle creating a more gradual change.