Rotational molding, also known as rotomolding or rotational casting, is a manufacturing process used to produce hollow plastic parts. This process involves heating a mold that contains the plastic material, and then rotating the mold in multiple axes to evenly distribute the material around the interior of the mold. Once the plastic has cooled and...

Hot wire foam cutting is a popular technique used to cut and shape polystyrene foam, also known as expanded polystyrene (EPS), extruded polystyrene (XPS), and other foam materials. The process uses a heated wire to melt and cut through the foam material, allowing for precision cuts and intricate shapes. Hot wire foam cutting is commonly...

https://engineeringtechnology.org/manufacturing/casting-processes/polymer-casting/

https://engineeringtechnology.org/manufacturing/separating-processes/machining-processes/machining-parameters/machining-plastics/

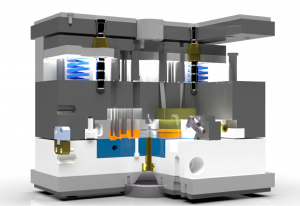

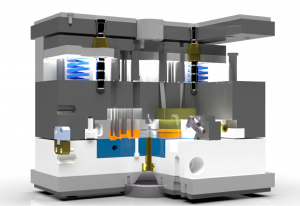

Injection molding is a popular manufacturing process used to produce a wide range of plastic products, from small components to large parts, with high precision and consistency. The process involves melting plastic pellets and injecting them into a mold cavity under high pressure to create the desired shape. Injection molding is widely used in a...

Extrusion is a common manufacturing process used to create continuous lengths of products with a fixed cross-sectional profile. The process is commonly used to create plastic pipes, tubes, profiles, and sheeting. Extrusion is a continuous process that uses a plastic resin or compound, which is melted and then forced through a die to form the...

Composite materials, known for their exceptional strength-to-weight ratio, thermal stability, and corrosion resistance, have revolutionized numerous industries, from aerospace to automotive and beyond. However, the production of these advanced materials presents a set of complex challenges that manufacturers must navigate to harness their full potential. Tooling Design and Fabrication Tooling, the molds and dies used...

Compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into intricate shapes through the application of heat and pressure. Unlike other molding techniques that involve the injection of molten material, compression molding employs solid raw material or preforms, which are subjected to high pressure and...

Blow molding, a cornerstone of modern plastics engineering, entails the transformation of thermoplastic materials into a wide array of hollow shapes, ranging from bottles and containers to more complex structures. The process harnesses air pressure to shape molten plastic within a mold, allowing for the production of intricately designed and functional objects. The Blow Molding...

Rotational molding, also known as rotomolding or rotational casting, is a manufacturing process used...

Hot wire foam cutting is a popular technique used to cut and shape polystyrene foam, also known as expanded...

https://engineeringtechnology.org/manufacturing/casting-processes/polymer-casting/

https://engineeringtechnology.org/manufacturing/separating-processes/machining-processes/machining-parameters/machining-plastics/

...

Injection molding is a popular manufacturing process used to produce a wide range of plastic products,...

Overmolding is a manufacturing process that involves the injection molding of one material over another...

Injection molding is a widely used manufacturing process that allows for the efficient production of...

Warpage is the distortion or bending of a molded part caused by non-uniform cooling or improper part...

Sink Marks are depressions or shrinkage marks that occur on the surface of a molded part due to variations...

Flash is excess material that extends beyond the intended part geometry, typically found along the parting...