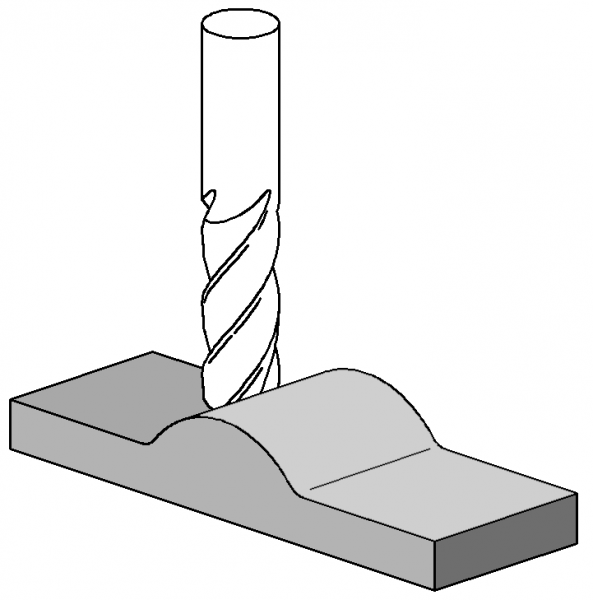

Contour milling is a machining process employed to shape and create complex, contoured surfaces on a workpiece. This milling technique involves the use of a specialized milling cutter with multiple cutting edges or inserts, which are strategically arranged along the cutter’s periphery.

Contour milling is utilized when intricate shapes, curves, and non-linear profiles are required. The cutter follows a path that matches the desired contour of the workpiece, allowing for the precise removal of material to achieve the intended shape. This process is crucial for manufacturing components with detailed or irregular designs, such as molds and complex parts used in industries like aerospace, automotive, and biomedical device manufacturing.

Contour milling offers the advantage of flexibility and precision. Machinists can program the milling machine or machining center to follow specific toolpaths that replicate intricate designs with high accuracy. The choice of cutting parameters, such as spindle speed, feed rate, and stepover distance, can be fine-tuned to ensure a smooth finish and maintain dimensional integrity.