Casting is a manufacturing process in which a liquid material is poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is then removed from the mold to complete the process. This process is used to produce parts with complex shapes that would be difficult or impossible to produce by other methods, such as machining. The liquid material used in casting is typically a metal, such as iron, steel, aluminum, or bronze, but it can also be a plastic or a ceramic material.

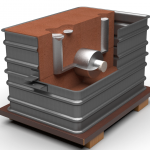

Sand Casting

Sand casting is a casting process that uses a mold made of sand to produce a metal part.

Polymer Casting

Polymer casting is a process that involves the use of liquid polymer material, which is poured into a mold and allowed to cure or harden into a desired shape.

Die Casting

Die casting is a manufacturing process that involves the use of metal molds, or dies, to produce complex and intricately shaped metal parts. The process involves melting metal into a liquid state and then forcing it into the mold under high pressure. The metal is then allowed to cool and solidify, taking the shape of...

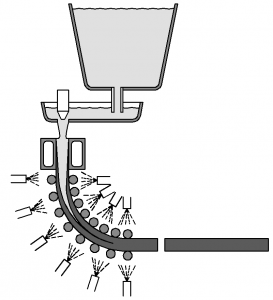

Continuous Casting

Continuous casting, also known as strand casting, is a manufacturing process used to produce large quantities of metal products in a continuous, uninterrupted manner. It is one of the most efficient and cost-effective methods of producing metal products, and is used extensively in the production of steel, aluminum, and other metals. Continuous Casting The basic...

Centrifugal Casting

Centrifugal casting is a metal casting process in which molten metal is poured into a rotating mold and solidifies under the influence of centrifugal force. The centrifugal force helps to distribute the molten metal evenly and eliminate any air pockets or voids that might be present, resulting in a uniform and dense casting. There are...

Rubber Mold Casting

Casting metal alloys in rubber molds is a popular method for creating complex and intricate metal parts. The process involves pouring molten metal into a rubber mold, which is then allowed to cool and solidify, resulting in a finished part. Generally, metals must have a low melting temperature. Rubber mold casting is often done as...

Rubber Plaster Mold Casting

Introduction Rubber-plaster mold casting, also known as "plaster casting" or "rubber mold casting," is a well-established metal casting process that combines the advantages of rubber patterns with plaster molds to produce intricate and detailed metal parts. This technique has been used for centuries and continues to find applications in various industries due to its versatility,...

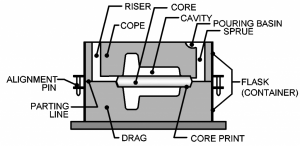

Core (Casting)

In casting, a core is a component used to shape the interior of a cast part. Cores are typically made...

Sand Casting

Sand casting is a casting process that uses a mold made of sand to produce a metal part.

Match Plate Pattern

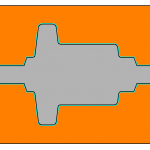

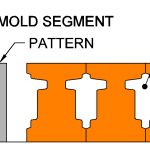

A match plate pattern is a single piece casting pattern that is commonly used in sand casting. It consists...

Flaskless Casting

Flaskless casting is a casting method that does not use flasks (i.e., the outer mold containers) to contain...

Sand Casting Procedure

The process begins with a pattern. Patterns should be:

Made of a stable material

Oversized...

Polymer Casting

Polymer casting is a process that involves the use of liquid polymer material, which is poured into a...

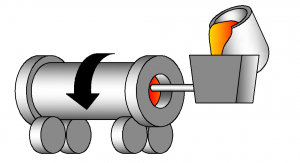

Die Casting

Die casting is a manufacturing process that involves the use of metal molds, or dies, to produce complex...

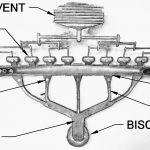

Hot and Cold Chamber Die Casting Machines

Hot chamber and cold chamber die casting machines are two of the most common types of die casting machines...