The correct selection of tools, workholding, cutting parameters, and milling techniques can significantly impact the quality, accuracy, and cost of the final part. In this section, we will explore the essential aspects of milling, including the types of milling operations, cutting parameters, and milling strategies to achieve optimal results.

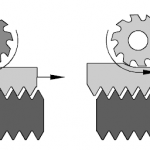

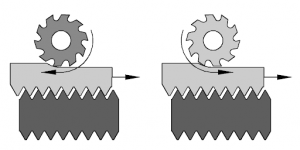

Climb Milling And Conventional Milling

In climb milling the rotation of the tool pulls the work off of the lead screw. Climb milling and conventional milling are two common cutting strategies used in milling operations. In climb milling, the cutting tool rotates in the same direction as the workpiece travels, while in conventional milling, the cutting tool rotates opposite to...

Right and Left Handed End Mills

The main differences between a right-handed and left-handed end mill is the direction in which they rotate and the direction in which the cutting forces are applied.. A right-handed end mill rotates clockwise when viewed from the top, while a left-handed end mill rotates counterclockwise. Right-handed and left handed end mills. The tool on the...

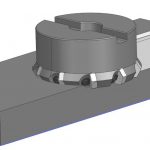

Boring Head – Mill

Boring is a machining process used to enlarge an existing hole to a precise diameter and surface finish. Boring can be performed on a variety of machines, including lathes, drill presses, and milling machines. In this article, we will focus on boring as it is done on a milling machine using a boring head. A...

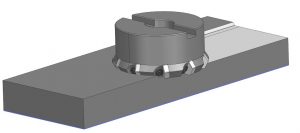

Face Milling

Face milling is a machining process employed in manufacturing and metalworking to create flat surfaces on a workpiece. This milling technique involves the use of a milling cutter with multiple cutting edges, known as inserts, arranged on the cutter's face. The cutter is mounted on a milling machine or machining center, and as it rotates,...

Contour Milling

Contour milling is a machining process employed to shape and create complex, contoured surfaces on a workpiece. This milling technique involves the use of a specialized milling cutter with multiple cutting edges or inserts, which are strategically arranged along the cutter's periphery. Contour milling is utilized when intricate shapes, curves, and non-linear profiles are required....

Climb Milling And Conventional Milling

In climb milling the rotation of the tool pulls the work off of the lead screw.

Climb milling and...

Right and Left Handed End Mills

The main differences between a right-handed and left-handed end mill is the direction in which they...

Boring Head - Mill

Boring is a machining process used to enlarge an existing hole to a precise diameter and surface finish....

Face Milling

Face milling is a machining process employed in manufacturing and metalworking to create flat surfaces...

Contour Milling

Contour milling is a machining process employed to shape and create complex, contoured surfaces on a...