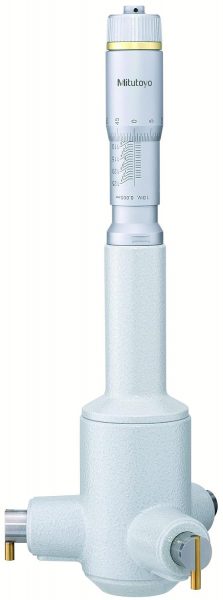

A three-point micrometer, also known as a three-point inside micrometer or a three-point internal micrometer, is a precision measurement tool used to measure the inside diameter of cylindrical objects such as holes, bores, or pipes. It is an essential tool in various industries where accurate measurements of internal dimensions are required, such as manufacturing, engineering, and quality control.

The term “three-point” refers to the measuring mechanism of the micrometer, which involves three measuring anvils or contact points that make contact with the inner surface of the object being measured. These anvils are positioned at equal intervals around the circumference of the micrometer’s spindle.

Three-point micrometers offer advantages over traditional two-point (or two-contact) micrometers:

- Accuracy: The three-point contact system provides better accuracy and eliminates errors due to variations in the shape or alignment of the object being measured.

- Self-Centering: The three-point system inherently centers the micrometer in the hole being measured, minimizing the chances of measurement errors caused by misalignment.

Three-point micrometers come in various sizes and designs, including mechanical versions with graduated scales and digital versions with electronic displays for more precise readings. They are a vital tool for quality control and ensuring that manufactured components meet specified tolerances and standards.