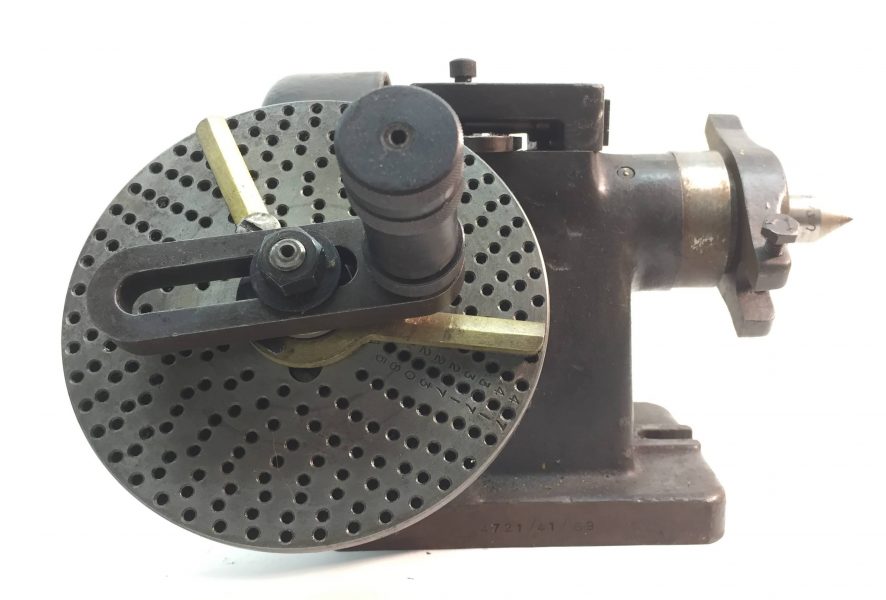

Workholding is a fundamental concept in manufacturing and machining processes, encompassing the methods and devices used to securely hold and position workpieces during various machining, assembly, or inspection operations. It involves the design and selection of fixtures, clamping systems, chucks, collets, and other mechanisms that ensure workpieces remain stable and accurately positioned. Workholding is essential for achieving precision and consistency in manufacturing, as it directly impacts the quality and efficiency of operations. Effective workholding not only keeps workpieces in place but also facilitates proper tool engagement, chip evacuation, and adherence to tight tolerances. Engineers and technicians carefully consider workholding solutions when designing parts, selecting cutting tools, and optimizing production processes to ensure safe, efficient, and high-quality manufacturing.