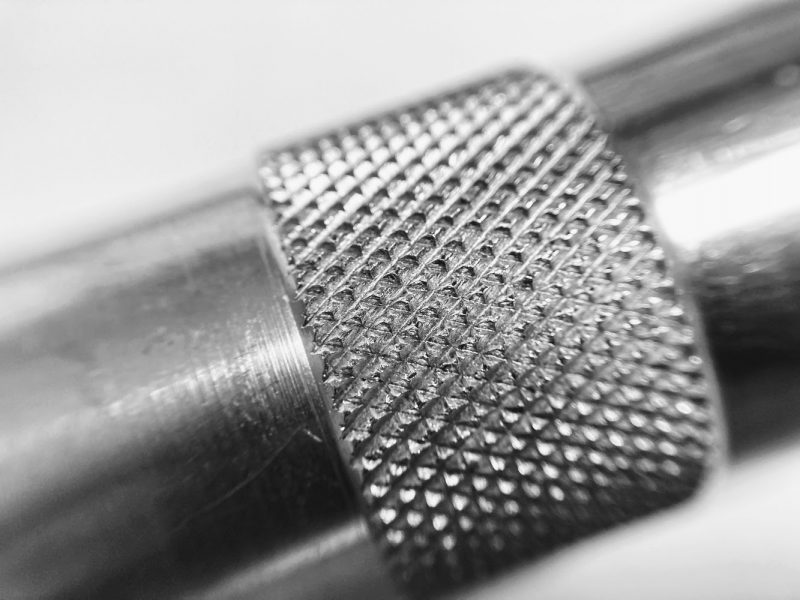

Knurls are a type of surface feature commonly applied to cylindrical or flat parts consisting of a ridged pattern.

Knurls are used for a variety of applications where a better grip is needed. They can be found on a wide range of products, from hand tools and machine parts to automotive components and consumer goods.

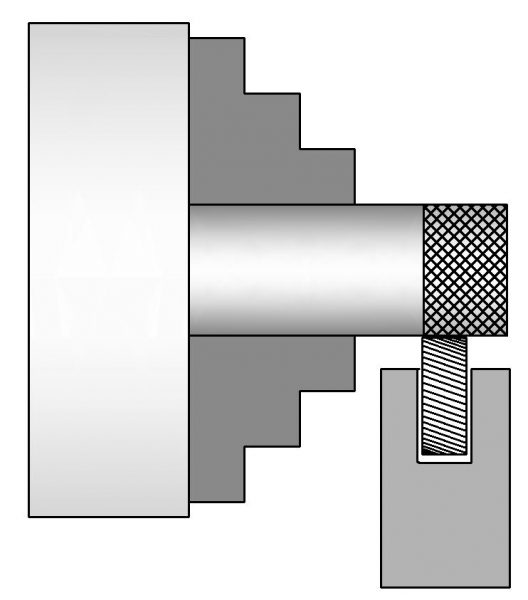

Knurls are also used for certain press-fitting applications, where the knurled surface is used to create a tight fit between two components. The knurled surface provides additional material that can be deformed during the press fitting operation. When press fitting knurled components into plastic or other ductile materials, the knurls will engage the material and provide a robust connection.

There are two main types of knurls: diamond knurls and straight knurls. Diamond knurls are the more common of the two and are made up of a series of diamond-shaped ridges that intersect at 90-degree angles. Straight knurls, on the other hand, have ridges that run parallel to the length of the part. Straight knurls may also be angular with left or right-hand orientation.

There are several methods of manufacturing knurls. One of the most common is through the use of a knurling tool, which presses (forms) the knurl pattern into the surface of the part. This can be done manually or with the use of a machine, such as a lathe. Another method is through the use of a cut knurling tool, which is rolled across the surface of the part to create the knurl pattern by removing metal.

When specifying a knurl, be sure to specify the type, pitch, and the diameter before and after knurling. If only part of a workpiece is to be knurled, the length of the knurl should be specified.

See: ASME B94.6

See also: ASME Y14.5-12018 S 4.5.18 and Knurls & Knurling