Manufacturing processes are the methods and techniques used to create products from raw materials or components. These processes typically involve a series of steps that transform materials into finished products. There are a wide variety of manufacturing processes used in industry, including casting, machining, welding, and forming. Each process has its own advantages and limitations, and the choice of process depends on factors such as the desired shape and size of the final product, the material being used, the required accuracy and finish, and the quantity of products to be produced. The goal of all manufacturing processes is to create products that meet the required specifications, are of high quality, and can be produced efficiently and cost-effectively.

Casting Processes

Casting is a manufacturing process in which a liquid material is poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify.

Forming Processes

Forming ProcessesSheet, Wire, and Tube Forming Processes Section Bending Wire Winding Sheet Metal Processes Shearing Right Angle Shearing Slitting (Sheet Metal Process) Punching Blanking (Sheet Metal Process) Turret Punch Press Bending (Sheet Metal Process) Sheet Metal Brakes Automated Bending Centers Press Brakes Incremental Sheet Forming Embossing Spinning Stamping Bulk Forming Processes Forming is a category...

Polymer Processes

Polymer manufacturing processes are widely used in the production of a diverse range of products such as consumer goods, packaging, automotive components, medical devices, and more. These processes involve shaping and forming polymers, which are large molecules made up of repeating subunits, into various shapes and forms. The most common polymer manufacturing processes include injection...

Surface and Edge Modification

Surface and Edge ModificationFunctional and Decorative Texturing Half-Moon Flaking Laser Texturing Surface Texture: Roughness, Waviness and Lay Surface Texture: Lay Crossed Lay Coatings Organic Coatings Primers Drying Oils Varnish Spirit Varnish (Shellac) Lacquer Enamels Latex Paints Bituminous Coatings Synthetic Coating Resins Coating Methods Spray Coating Powder Coating Electrocoating (E-Coating) Inorganic Coatings Conversion Coatings Aluminum Anodizing...

Thermal Joining

Thermal joining is a category of processes for joining two or more materials together using heat. These process involves applying heat (and sometimes pressure) to the materials until they reach a molten or semi-molten state, allowing them to flow together and form a strong bond. There are several techniques for thermal joining, including welding, brazing,...

Glass Processes

Glass production processes involve transforming raw materials, primarily silica sand, soda ash, and limestone, into glass products through high-temperature melting in a furnace. Once molten, the glass is shaped into various products using techniques like blowing, pressing, or drawing. After forming, the glass is often annealed to relieve internal stresses and improve strength. Further processing...

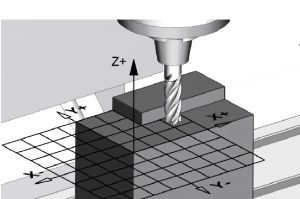

Computer Numerical Control (CNC)

Computer Numerical Control (CNC) is a modern manufacturing technology that utilizes computers to control the operation of machinery and tools in various industries. In CNC systems, computer programs and software are used to automate and precisely control the movement and operation of machines, such as lathes, mills, routers, and more. This automation allows for the...

Additive Manufacturing

Additive manufacturing, often referred to as 3D printing, is a manufacturing process that builds three-dimensional objects layer by layer, directly from a digital design file. Unlike traditional subtractive manufacturing methods, which involve cutting, drilling, or shaping material to create a final product, additive manufacturing adds material in a sequential and precise manner. This process offers...

Workholding

Workholding is a fundamental concept in manufacturing and machining processes, encompassing the methods and devices used to securely hold and position workpieces during various machining, assembly, or inspection operations. It involves the design and selection of fixtures, clamping systems, chucks, collets, and other mechanisms that ensure workpieces remain stable and accurately positioned. Workholding is essential...

Separating Processes

Separating processes are those manufacturing processes that involve material removal.

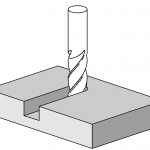

Machining Processes (Mechanical Separating)

Machining is a class of manufacturing processes that change the shape of a workpiece by removing metal...

Machine Tools

Machine tools are a fundamental cornerstone of modern manufacturing and engineering, playing a pivotal...

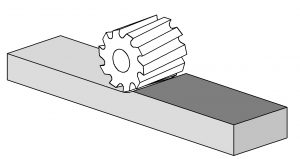

Milling Operations, Tools, and Strategies

The correct selection of tools, workholding, cutting parameters, and milling techniques can significantly...

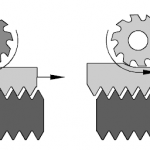

Climb Milling And Conventional Milling

In climb milling the rotation of the tool pulls the work off of the lead screw.

Climb milling and...

Right and Left Handed End Mills

The main differences between a right-handed and left-handed end mill is the direction in which they...

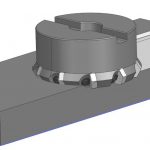

Boring Head - Mill

Boring is a machining process used to enlarge an existing hole to a precise diameter and surface finish....

Face Milling

Face milling is a machining process employed in manufacturing and metalworking to create flat surfaces...

Contour Milling

Contour milling is a machining process employed to shape and create complex, contoured surfaces on a...