First and foremost, the human element is at the core of the need for machine shop safety. Students must recognize that the machinery and tools in a machine shop are powerful and unforgiving. Neglecting safety precautions can lead to severe injuries or even fatalities. Prioritizing safety is not just about following rules; it's about safeguarding...

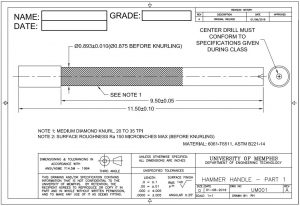

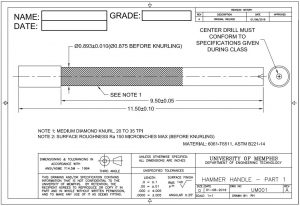

The hammer handle is machined in two phases. In Part A, the hammer blank is sawed to length, layed out, center drilled, straight turned, and knurled. Part 2 - Machining the Handle (Part A)Machining Lab – Sawing Machining Lab – Layout Machining Lab – Center Drilling Machining Lab – Straight Turning Machining Lab – Knurling

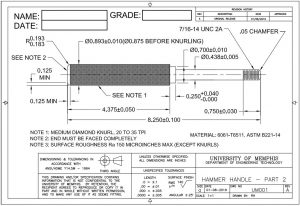

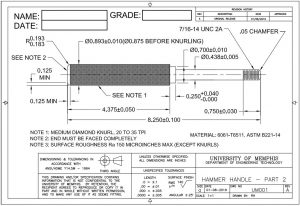

In Part B of the hammer project, students will machine a shoulder, face, chamfer and thread the handle. Part 3 - Machining the Handle (Part B)Machining Lab – Turning a Shoulder Machining Lab – Face, Chamfer, Thread, Form Turning HAMMER-UM001-HANDLE-PART-2Download

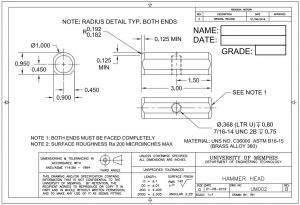

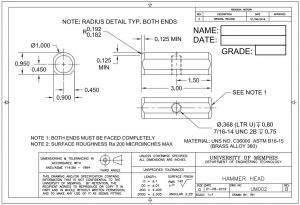

Making the hammer head is the final part of the machining lab. The brass hammer head is sawed using a band saw and faced to length. Then the mill is used to machine three flats. The hammer is finished by drilling and tapping the attachment hole. HAMMER-UM001-HEADDownload

First and foremost, the human element is at the core of the need for machine shop safety. Students must...

The hammer handle is machined in two phases. In Part A, the hammer blank is sawed to length, layed...

In this video, the blank material (6061-T6511 Aluminum) is cut to length.

https://www.youtube.com/watch?v=tJ3LmmoYRJ4

...

Laying out a workpiece is an essential skill in the machine shop. This videos introduces several layout...

Long workpieces must be properly supported. A center drill is used to drill a conical hole in the end...

Straight turning is the fundamental lathe process. In this video students are introduced to the lathe...

Knurling forms a diamond pattern (knurls ) on the workpiece. The knurling tool must be fed into the...

In Part B of the hammer project, students will machine a shoulder, face, chamfer and thread the handle....

It is essential to be able to control both the diameter and length of a machined feature. This video...

In this video the hammer handle is finished.

https://www.youtube.com/watch?v=601M1l7-RHM