The process begins with a pattern. Patterns should be:

- Made of a stable material

- Oversized to accommodate shrinkage

- Include draft angles

- Include generous fillets and rounds (avoid sharp corners)

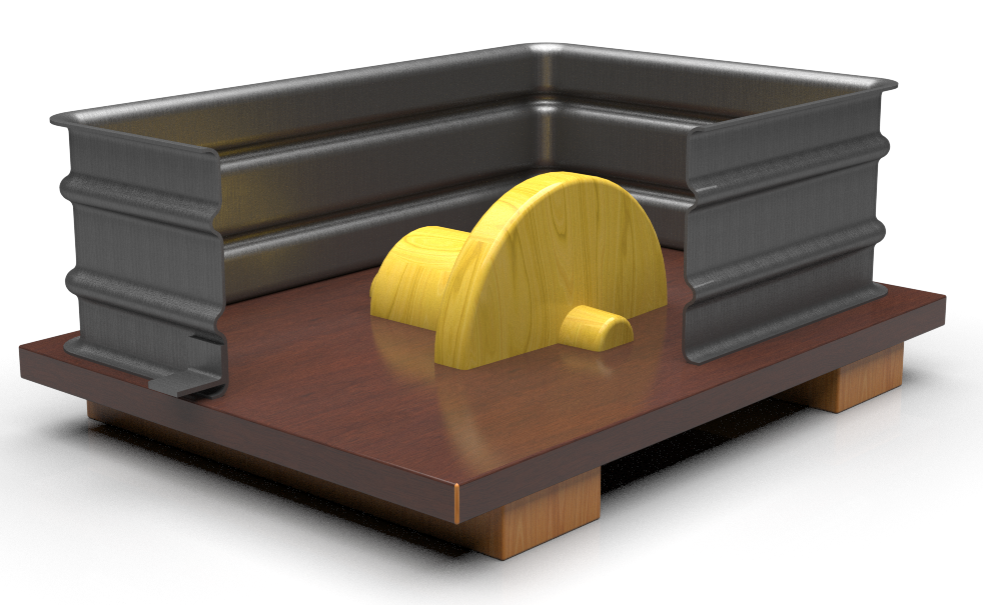

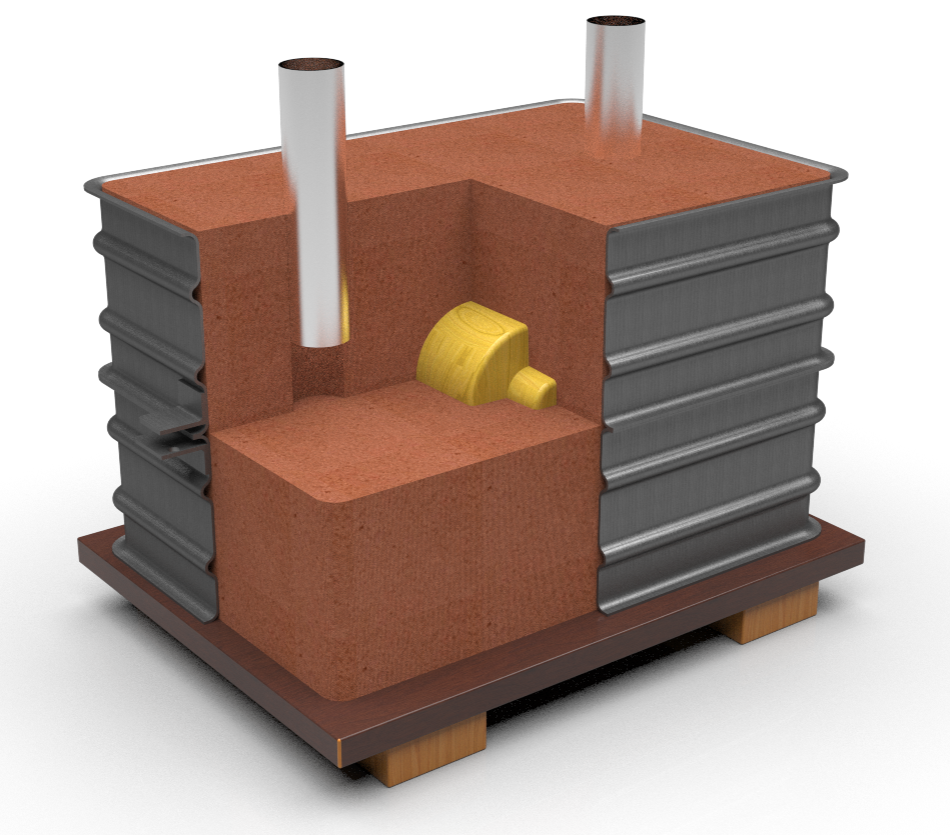

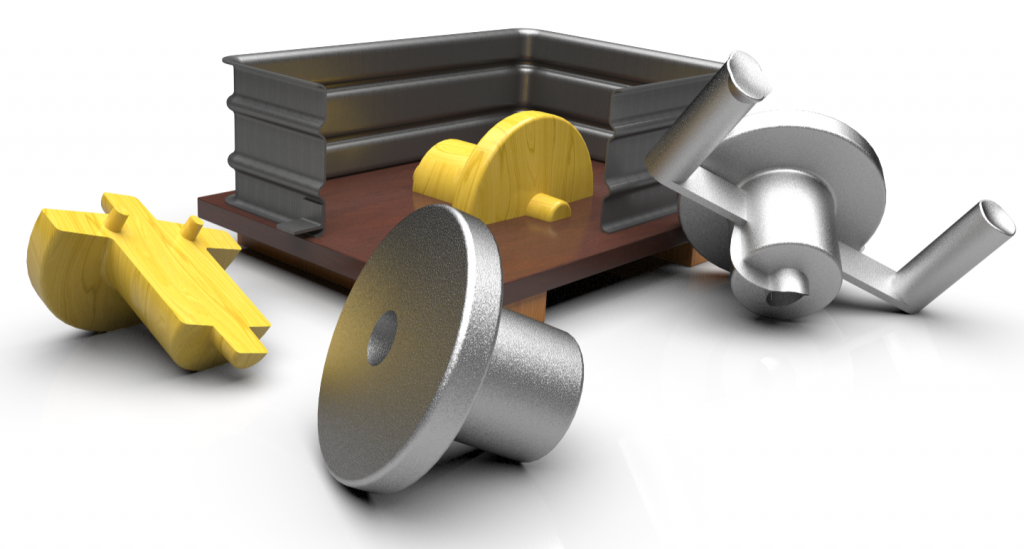

Here, a split pattern is used. The two halves of the split pattern nest together.

The split pattern shown with cutaway of flask.

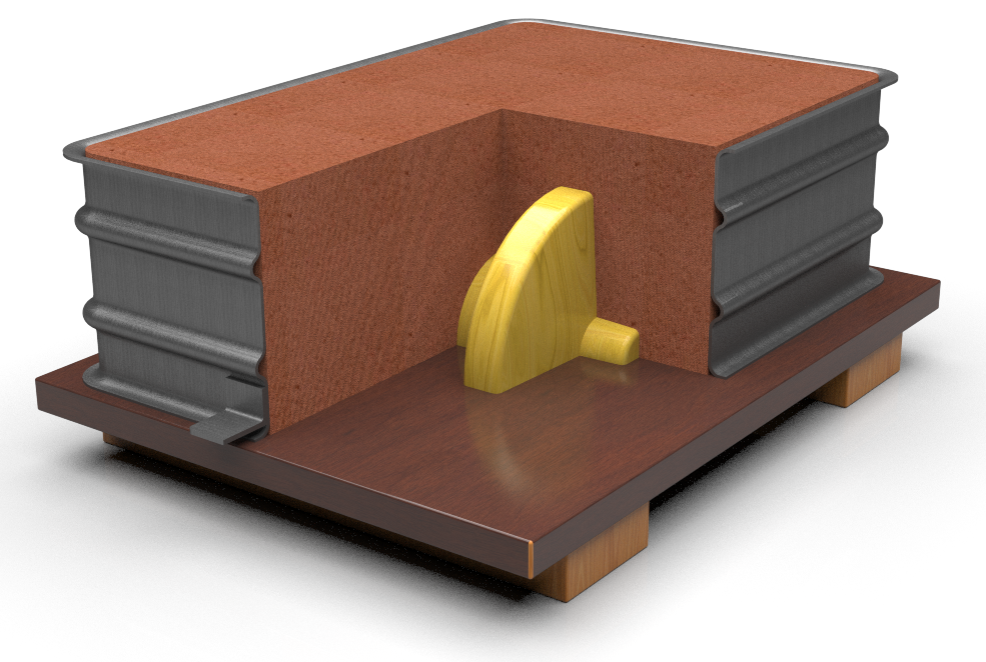

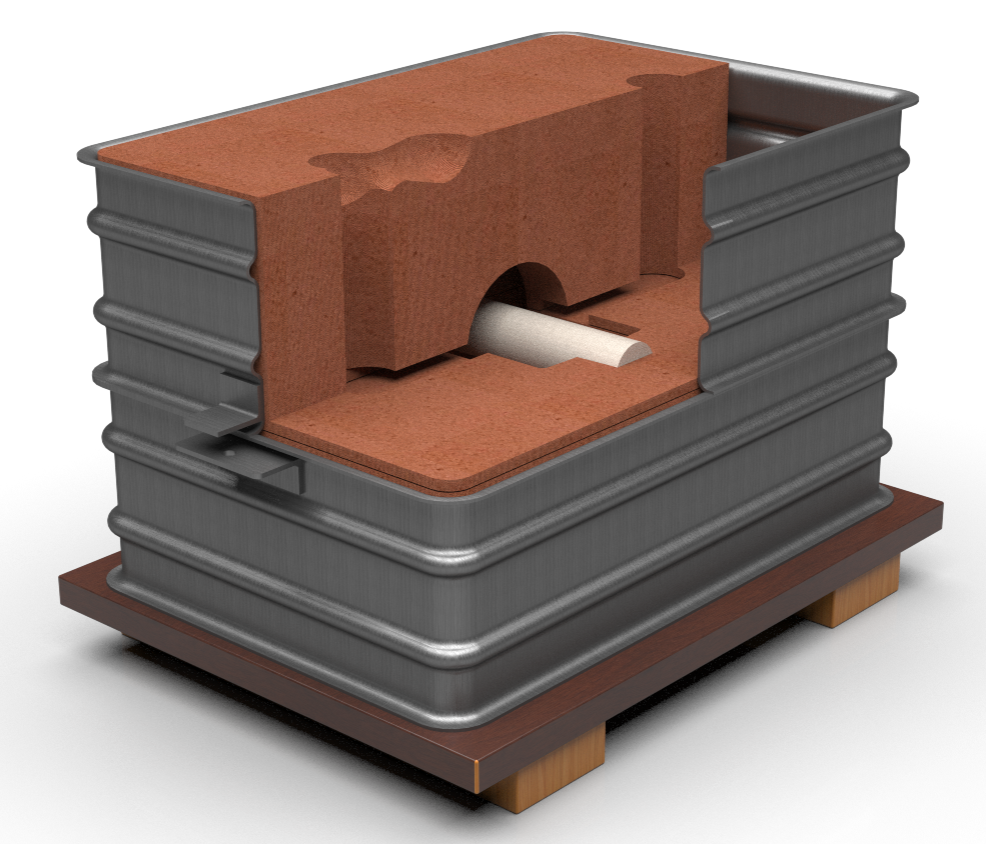

The pattern is covered with parting compound and sand is rammed into the flask to form the drag. Excess sand is removed by a process known as strickling.

When the drag has been rammed and strickled, it is inverted and the cope half of the pattern is placed.

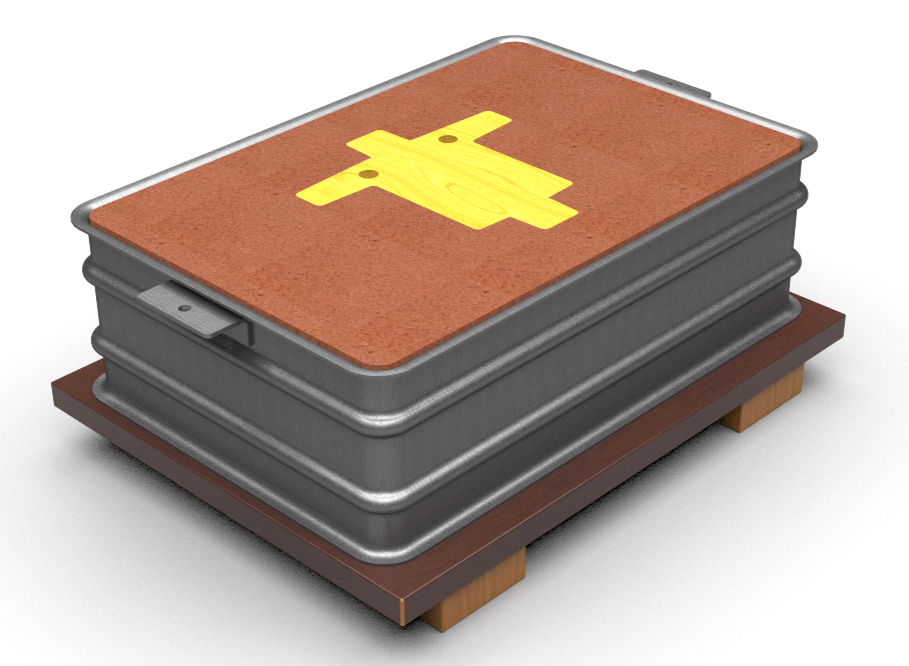

Parting compound is added on top of the cope half of the pattern and the cope is rammed with sand.

With the cope rammed, sprue and risers are cut.

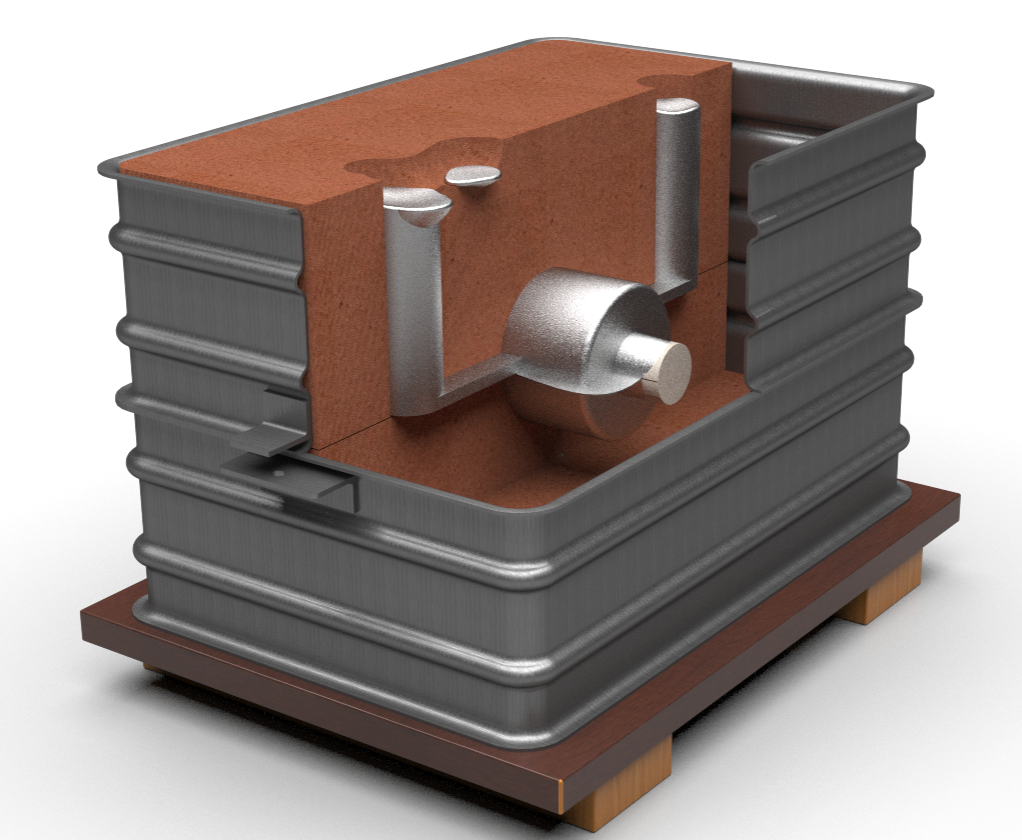

The mold is then disassembled and runners are cut from the sprue and riser. If cores are used, they are inserted into the core prints at this time.

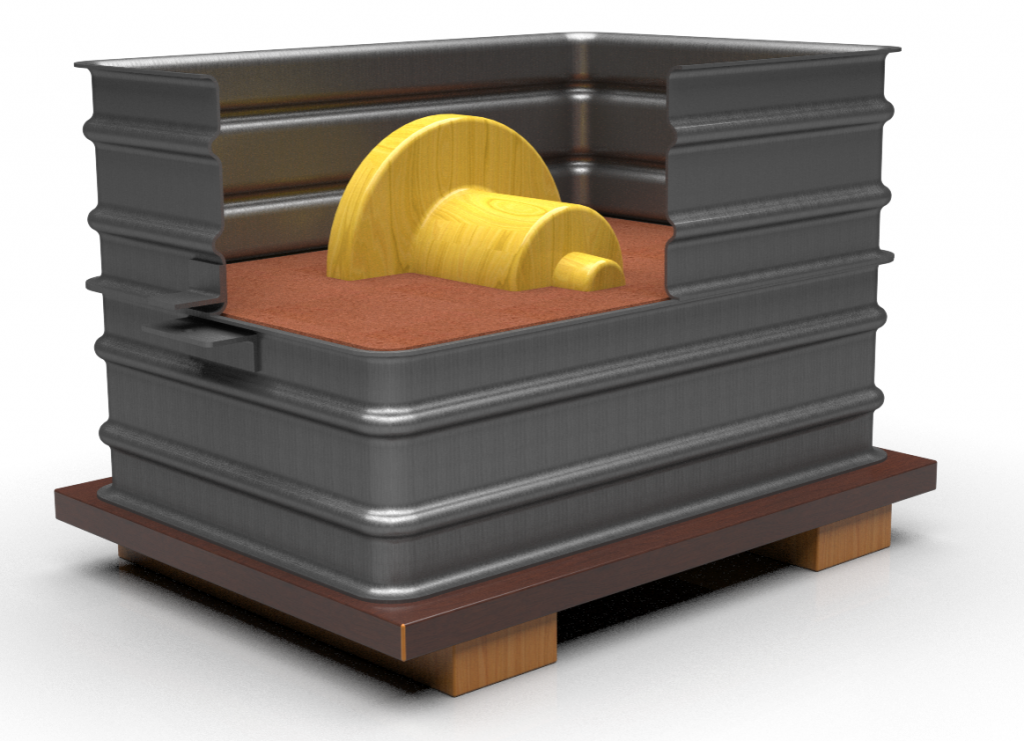

The mold is then re-assembled and is ready to be poured.

The mold is poured and allowed to cool.

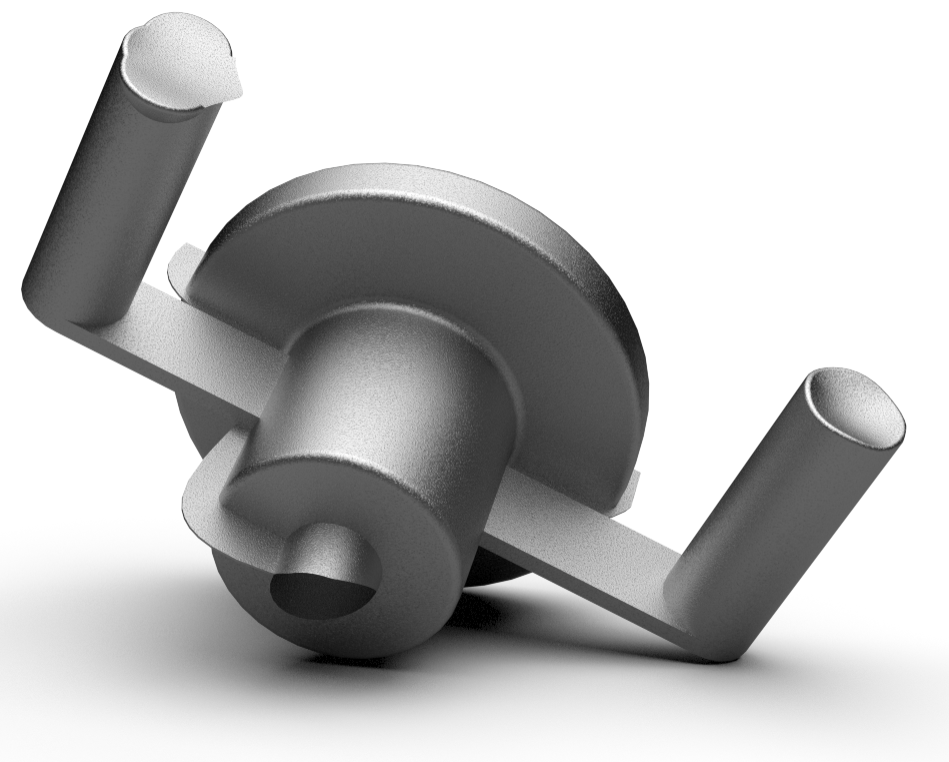

When the part has cooled it is removed from the sand.

Gates and runners must then be removed. This process is known as fettling.

References

“Innovative Latest Technology and Measurement Systems of Refractory Coatings. Chandan Panda, Forace Polymers Pvt. Ltd. https://www.foundry-planet.com/fileadmin/redakteur/pdf-dateien/25-Chandan-Panda.pdf Accessed 16 Mar. 2021.

“Phenolic Urethane No Bake Process.” HA-International, https://www.ha-international.com/content/products/resins/nobake.aspx. Accessed 16 Mar. 2021.

“StackPath.” StackPath, https://www.foundrymag.com/molds-cores/media-gallery/21153249/phenolic-urethane-cold-box-environmental-advantages-ha-international. Accessed 16 Mar. 2021.