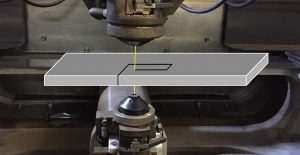

lectrical Discharge Machining (EDM) is a precision machining process that utilizes electrical sparks to remove material from a workpiece. In EDM, a tool electrode and the workpiece are submerged in a dielectric fluid (usually oil or deionized water) but do not make direct physical contact. When an electrical voltage is applied between the tool and the workpiece, intense electrical discharges or sparks occur in the small gap between them. These sparks generate extremely high temperatures, melting or vaporizing small bits of material from both the tool and the workpiece. As the process continues, the material is gradually eroded, shaping the workpiece to the desired form. EDM is known for its ability to cut intricate shapes, very hard materials, and parts with tight tolerances, making it valuable in industries like aerospace, toolmaking, and mold production.