Injection molding is a popular manufacturing process used to produce a wide range of plastic products, from small components to large parts, with high precision and consistency. The process involves melting plastic pellets and injecting them into a mold cavity under high pressure to create the desired shape. Injection molding is widely used in a variety of industries, including automotive, electronics, packaging, medical, and consumer goods.

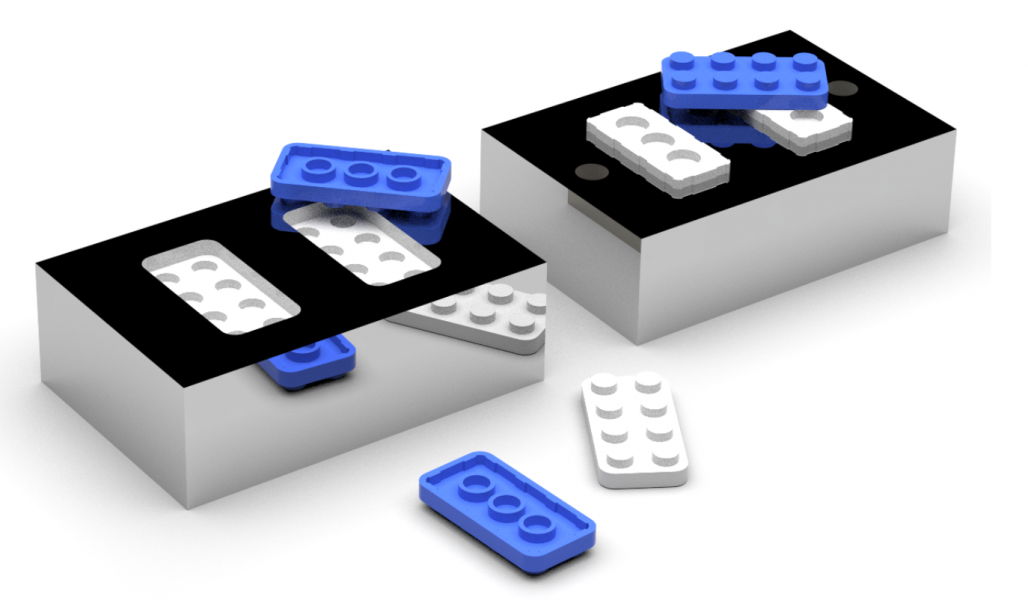

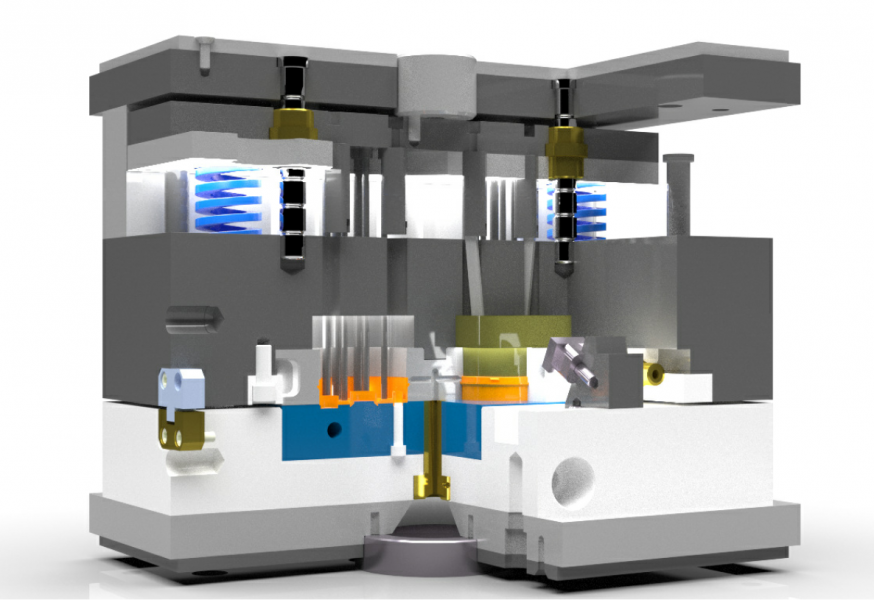

The injection molding process begins with the raw plastic material, which is typically in the form of pellets. These pellets are fed into a hopper, where they are heated and melted to a liquid state. The melted plastic is then injected into a mold cavity under high pressure, typically ranging from 5,000 to 30,000 psi. The mold cavity is carefully designed to create the desired shape and features of the finished product, including the surface finish, texture, and dimensional accuracy.

Once the plastic has been injected into the mold cavity, it is allowed to cool and solidify, which typically takes a few seconds to a few minutes, depending on the size and complexity of the part. Once the part has solidified, the mold is opened, and the part is ejected from the mold cavity. The process is then repeated to produce additional parts.

Injection molding offers several advantages over other manufacturing processes, including high production rates, consistent part quality, and the ability to produce parts with complex shapes and features. The process is also highly automated, which reduces labor costs and increases efficiency. Additionally, injection molding allows for the use of a wide range of plastic materials, including thermoplastics, thermosets, and elastomers, providing flexibility in material selection and performance characteristics.

Injection molding is an efficient and cost-effective way to produce high-quality plastic parts with complex geometries and tight tolerances. With its versatility and ability to produce large volumes of parts quickly and consistently, injection molding has become a widely used manufacturing process in numerous industries, making it an essential component of modern manufacturing.