Flaskless casting is a casting method that does not use flasks (i.e., the outer mold containers) to contain the molding sand. Instead, the molding sand is compacted directly onto the pattern in a compacting machine, which is then used to produce the mold.

In traditional casting methods, the mold is made in two halves, known as the cope and drag, and is contained within a flask. The molding sand is packed into the flask, and the pattern is placed in the center of the flask. The mold is then closed and the molten metal is poured into the mold.

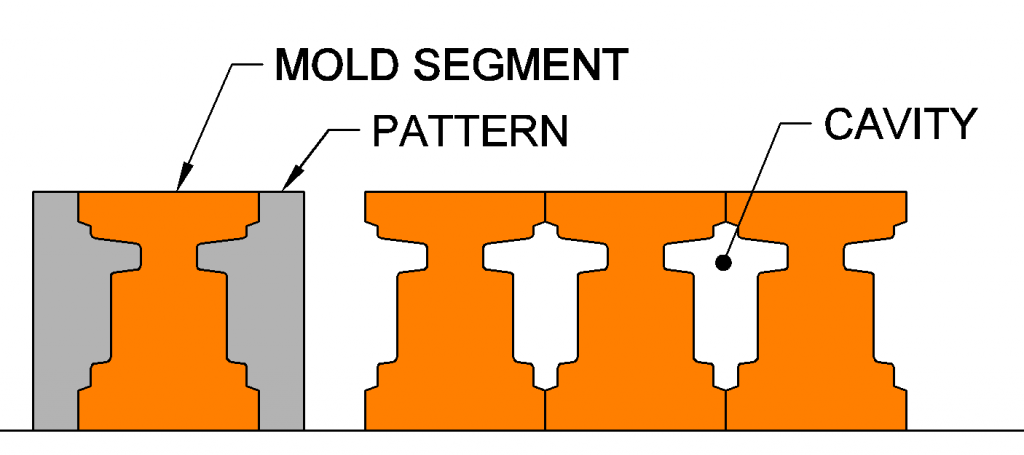

Flaskless casting, on the other hand, eliminates the need for the flasks and streamlines the casting process. The molding sand is compacted directly onto the pattern in the compacting machine, and the mold is produced in a single step. The mold is then placed into a casting machine, and the molten metal is poured directly into the mold.

Flaskless casting has several advantages over traditional casting methods. It is faster and more efficient, as it eliminates the need for the separate flask-making step. It also reduces the cost of production by reducing the amount of material and labor required. Additionally, the elimination of the flask makes it easier to produce smaller, more intricate castings, as the mold can be made directly onto the pattern.

References

“ATHI-Vertical Parting Flaskless Molding Machine.” Www.youtube.com, www.youtube.com/watch?v=12zsEVfPaVg. Accessed 10 Feb. 2023.

“Vertical Moulding for Green Sand Casting Explained.” Www.disagroup.com, www.disagroup.com/en-us/vertical-explained. Accessed 10 Feb. 2023.