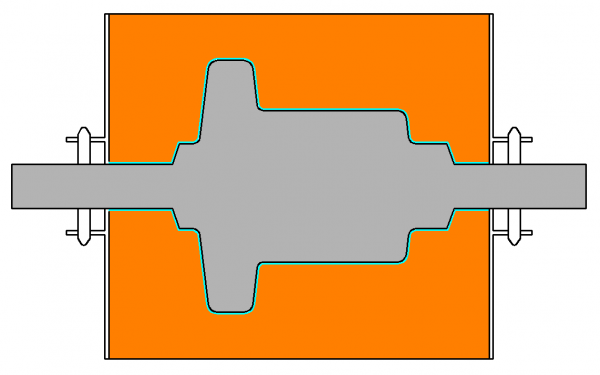

A match plate pattern is a single piece casting pattern that is commonly used in sand casting. It consists of two opposing sides, the cope and the drag, each with a specific function in the casting process. The cope side has the positive form of the part to be cast, while the drag side has the negative form of the part.

The match plate pattern is placed in a mold box and the molding sand is packed around it to create the mold cavity. Once the mold is complete, the match plate pattern is removed and the molten metal is poured into the mold cavity. The metal solidifies and the match plate pattern is separated from the cast part, leaving the desired metal object.

Match plate patterns are used in sand casting because they provide a quick and efficient way to produce multiples of the same part, and they allow for easy removal of the pattern after the casting process is complete. Additionally, they make it possible to cast large and complex parts that would be difficult or impossible to produce using other casting methods.