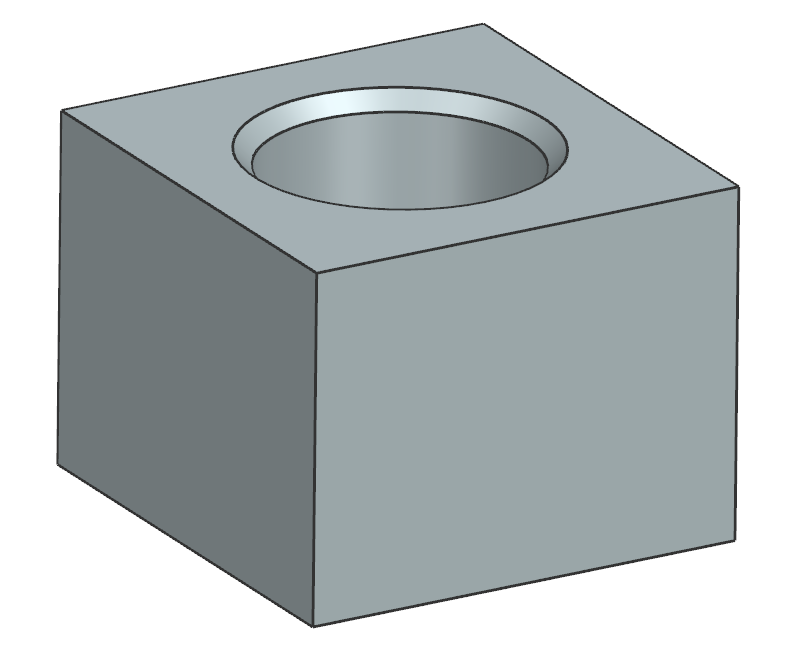

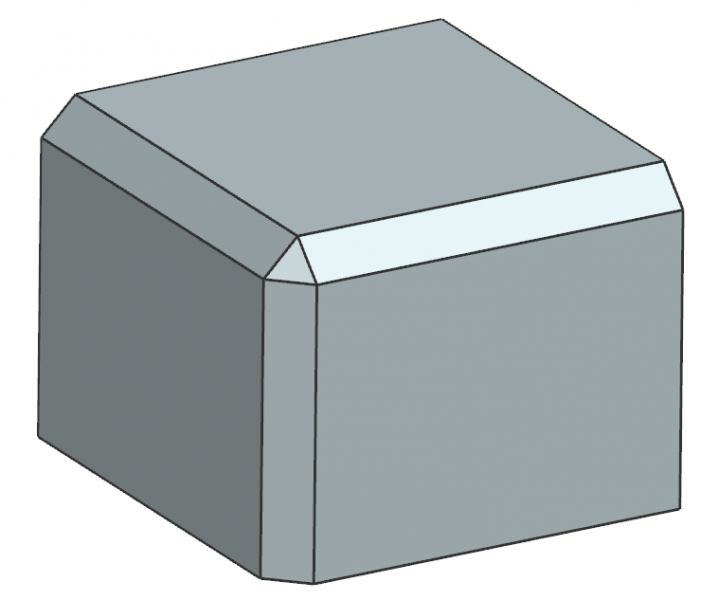

Chamfers are a type of machining feature that is used to create a beveled edge on the corner or edge of a part. This beveled edge, known as a chamfer, can serve several purposes, such as improving the appearance of the part, reducing stress concentrations, or allowing the part to fit into an assembly more easily.

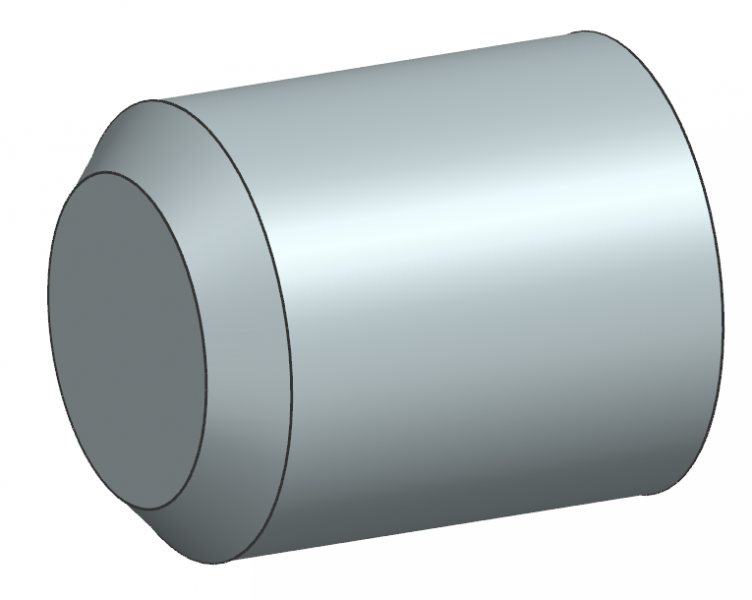

Chamfers are commonly used in manufacturing and engineering applications, and can be created using a variety of tools and methods. Some of the most common methods include milling, grinding, and hand tools such as files or deburring tools.

The size and shape of a chamfer can vary depending on the application and requirements of the part. In general, the angle of a chamfer is measured in degrees, with 45-degree and 90-degree chamfers being the most common. The size of the chamfer is typically specified by the width or depth of the bevel.

Chamfers can be used on a wide variety of parts, including machine parts, bolts, screws, and other fasteners. They can also be used on edges or corners of parts that will be handled frequently, such as consumer products or tools.

In addition to improving the appearance and functionality of a part, chamfers can also have practical benefits in terms of manufacturing and assembly. By adding a chamfer to a part, it can be easier to remove it from a mold or fixture, reducing the risk of damage to the part or the equipment. Chamfers can also make it easier to assemble parts that need to fit together precisely, by providing a tapered edge that allows for easier alignment and insertion.