In a machine shop, layout dye is used as a marking agent for identifying and marking various metal parts and components. The purpose of using layout dye is to provide a clear, precise and permanent mark that can be easily seen on metal surfaces and is resistant to abrasion, wear and tear. The dye can be used for a variety of applications, including inspection, assembly, and tooling.

There different of layout dyes that are commonly used in machine shops, each with its own unique properties and advantages:

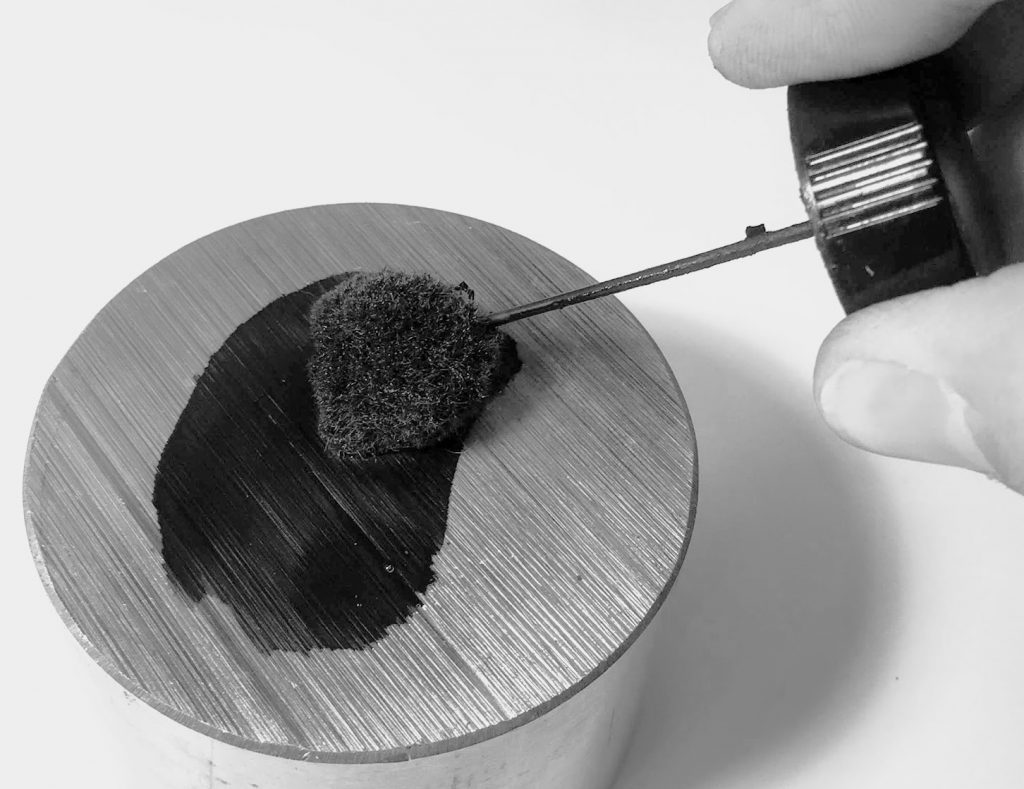

- Marking Ink: Marking ink is a type of layout dye that is applied to metal surfaces using a pen, brush or stamp. The ink dries quickly and provides a clear, permanent mark that is resistant to wear and tear. This type of layout dye is suitable for small-scale marking applications, such as marking identification numbers on small metal components.

- Marking Spray: Marking spray is a type of layout dye that is applied to metal surfaces using an aerosol can. The spray provides a fast-drying and permanent mark that is resistant to wear and tear. This type of layout dye is suitable for large-scale marking applications, such as marking identification numbers on large metal components.

Regardless of the type of layout dye used, it is important to carefully follow the manufacturer’s instructions and to use appropriate protective equipment when handling the dye. By using layout dye, machine shops can effectively and efficiently mark metal parts and components, helping to streamline their operations and ensure the accuracy and quality of their products.