The history of CNC (Computer Numerical Control) technology dates back to the mid-20th century. In the late 1940s and early 1950s, researchers and engineers began exploring ways to automate machine tool operations using electronic controls. Early efforts involved analog computers and punch-card systems to control machine movements.

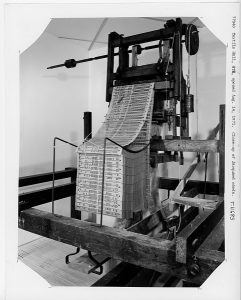

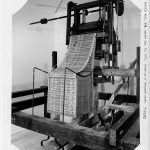

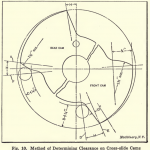

The breakthrough came in the late 1950s when John T. Parsons and his team at the Massachusetts Institute of Technology (MIT) developed the concept of numerical control (see the patent). They combined digital computers with existing machine tools, effectively creating the foundation for CNC technology. The first CNC machine, a Cincinnati Hydrotel milling machine retrofitted with a computer control system, was introduced in the early 1960s.

As computing technology advanced, CNC systems evolved from punch-card readers to more sophisticated computer interfaces. The 1970s saw the adoption of microprocessors, which improved the processing speed and capabilities of CNC machines. This led to increased precision, complexity, and versatility in machining operations.

The 1980s marked a significant turning point with the integration of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software with CNC systems. This merger enabled seamless design-to-production workflows and paved the way for 3D machining.

Since then, CNC technology has continued to advance, incorporating features like multi-axis control, adaptive machining, and high-speed machining. CNC machines are now capable of producing intricate and precise components across various industries with minimal human intervention.

Today, CNC technology is an integral part of modern manufacturing, contributing to efficiency, accuracy, and automation. It has shaped the way products are designed, developed, and produced, revolutionizing industries ranging from aerospace and automotive to electronics and medical devices.

Scientific American

Vol. 187, No. 3, September 1952

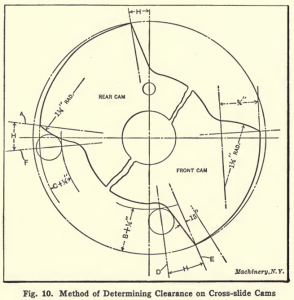

An Automatic Machine Tool

References

- Video: Sperry Numerical Control 1

- Video: Sperry Numerical Control 2

Pease, William. “An Automatic Machine Tool.” Scientific American, vol. 187, no. 3, 1952, pp. 101–115, www.jstor.org/stable/24950784?seq=1#metadata_info_tab_contents. Accessed 30 Aug. 2023.